Mixing Process In The Rubber Recycling Industry

Why Choose Us

Let’s Start Work Together

- +86-15976867748

- Contact@labkneader.com

- Gangkou Rd, Luo Yong Country, Xinhe, Wanjiang,DongGuan City,GuangDong,China

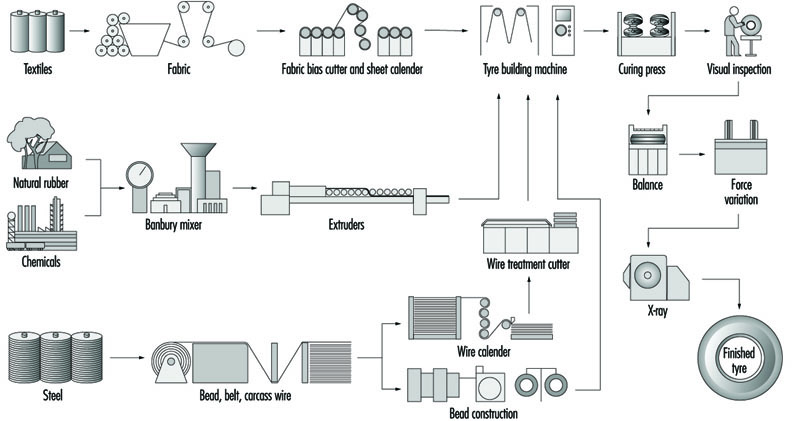

Tire manufacturing is composed of several kinds of components that result in safe, economical and environmentally friendly tire products.

The production is a complex process, but can be seperate into three main processes: tire preparation, tire production and tire building.

Tire Preparation includes fabric cord manufacturing, bead and Banbury mixers. While tire production includes fabric cord calendering, fabric material cutting, steel belt calendering, steel belt cutting, inner liner calendaring and tread and sidewall extruding. And tire building includes tire curing, visual inspections, x-ray inspections, balance inspections and force and movement inspections.

Compounding and Banbury Mixing

Compounding is the operation of bringing together all the ingredients required to mix a batch of rubber compound.

A Banbury mixer combines rubber stock, carbon black and other chemical ingredients to create a compound rubber material which are great effect by Time, heat and raw materials on the process of production.

The Belt & Ply

A process called “calendaring”, which involves the Belt and Ply comes next! The calender operation continues to shape rubber.

Calendaring machine is one heavy-duty machine ,which come with 1 or 2 ,3,4 rollers , through which the rubber sheets are forced .The roller calendar machine presses the fabric or steel cords onto and into the rubber during a number of steps, firstly combining the rubber compound and cords (at controlled tensions) to create a continuous sheet of rubber and cord composite. Once in sheet form, the rubber sheets are passed through more rollers to optimise bonding of the different elements and later cut into different sizes, shapes and angles depending on the required contour of the tyres being created.

Milling

After the compound material come from banbury mixer ,it need to go to the next step ,that is mixing mill .

Once the rubber is cooled, it’s sent to a special two roll mill where the rubber is cut into strips that will form the basic structure of your tyre. At the milling stage, other elements of the tyre are prepared, some of which are then coated in another type of rubber.

Two roll mill is widely used in rubber, plastics industries. Such as polyolefin, PVC, film, coil, profile production and polymer blending, pigments, masterbatch, stabilizers, stabilizers and so on. The main purpose is to test raw materials’s physical properties change and contrast after mixing. Such as color dispersion, light transmission, substance table.

In the mixing stage of tire manufacturing, the raw materials are mixed together and heated at a temperature of approximately 120 degrees Celsius.

Curing and Vulcanizing

Once the build process has been completed, the tyre then goes into Curing. Tyres are cured in batches using chemical processes at high temperatures and pressures. The uncured tyre is placed into a mould at a certain temperature and the tyre compound then flows into the mould, creating the tyre details and sidewall design. After vulcanization by vulcanizer press machine, the vulcanised rubber perform more strength, resilient and elastic .

After the rubber become wasted , all rubber is actually recyclable

Modern tire technology integrate chemistry, physics and engineering ,which thus provide people a high degree of comfort, performance, efficiency, reliability and safety.

There is a complete industry dedicated to the rubber recycling process. In the typical rubber recycling process, rubber is collected, shredded, sorted, and finally devulcanized to transform waste rubber into raw material.

There are many befefits that recycling wasted rubber :

* Reducing the amount of rubber that ends up in landfills

* Conserving energy . As the process of reclaiming and repurposing rubber need mucb less energy compared to producing new rubber

* Conserves space in landfills, and reduces environmental pollution

Here are some main resource for recycling material :

Scrap Tire: Scrap tires are the most commonly recycled rubber product. These tires make up the majority of the rubber materials that are recycled each year. Scrap tires are collected and processed to be reused in a variety of industrial, commercial and consumer products. These tires are ground into small granules and particles that can then be used as an ingredient in new rubber products such as rubberized asphalt, running tracks and roofing materials.

Reclaimed Rubber: Reclaimed rubber is rubber that has been repurposed from another product. Tire rubber is a popular form of reclaimed rubber, due to its durability and extended lifetime. In the reclaimed rubber process, rubber scraps are recycled and reprocessed until a new rubber product is formed. Commonly re-used for tires, shoe soles, construction materials and various types of adhesive, reclaimed rubber allows for manufacturers to save resources and money on operations.

Recycled Rubber: Recycled rubber is rubber that is melted and reused from scrap sources. This type of rubber is used in multiple applications and can be used to manufacture a variety of rubber-related products. It is highly durable, very versatile and allows a much wider range of applications than traditional rubber products. Recycled rubber can be used to make rubberized products such as floor mats, driveway sealants and hoses.

Tyre Rubber Recycling Process

Wasted tyres are main source of rubber material. To recycle the wasted rubber, it first needs to be cleaned and then made into a smaller, ideal size. The rubber is then placed into a granulator and transformed into crumb rubber – small fragmented pieces of rubber – to be used elsewhere, then into rubber disperion kneader ,and mixing mill etc .

So where are these reclaimed rubber used , here are just a few example that recycled rubber can be used:

• Astroturf

• Playground surfaces

• Non-slip mats

• Road surfaces and infrastructure

• Vehicle mats and interiors

• Hospital floors

• Gardening products and equipment