In the dynamic world of rubber processing, where precision and efficiency are paramount, PVC mixing mills stand as unsung heroes. These machines play a pivotal role in transforming raw rubber materials into the diverse and durable products that surround us every day. In this blog, we’ll take a deep dive into the world of PVC mixing mills, exploring their significance, intricate workings, and the transformative impact they have on the rubber industry.

1. The Heart of Rubber Processing: Understanding PVC Mixing Mills

Rubber processing is an intricate dance of precision and technique, and at the center of it all are PVC mixing mills. These machines are the workhorses that take raw rubber compounds and mold them into the versatile products we use in countless applications.

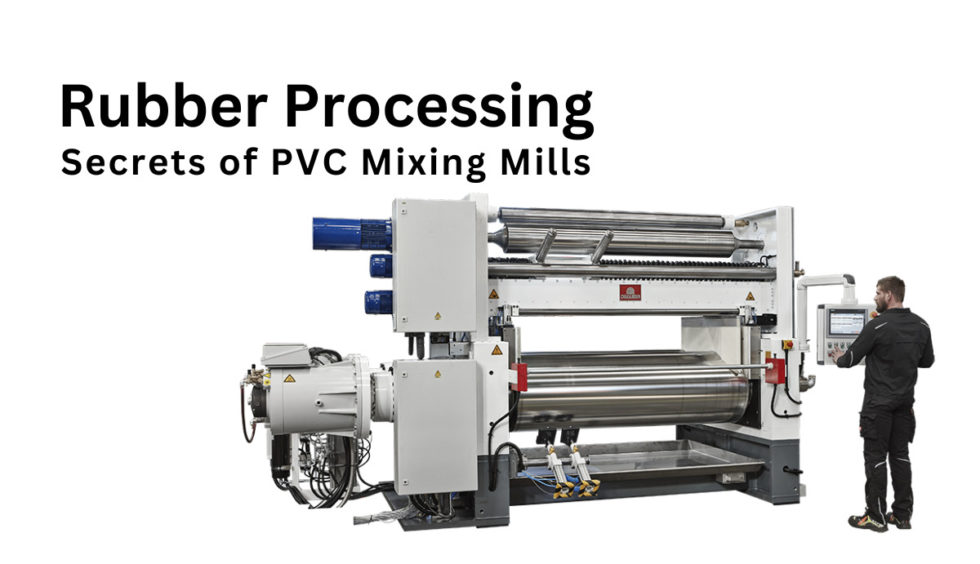

2. Inside the Machine: Anatomy of a PVC Mixing Mill

Let’s dissect the anatomy of a PVC mixing mill. From the rollers and gears to the cutting-edge technology embedded in the control systems, each component plays a crucial role in the mixing and processing of PVC and rubber compounds.

3. Innovation in Action: Advanced Features of Modern PVC Mixing Mills

Innovation in PVC mixing mills is a testament to the ever-evolving nature of the rubber processing industry. Explore the latest technological advancements that enhance efficiency, precision, and overall performance. From automated controls to real-time monitoring, discover how modern PVC mixing mills are pushing the boundaries of what’s possible.

4. Optimizing Rubber Formulations: The Role of PVC Mixing Mills

Precise mixing is the key to achieving optimal rubber formulations for specific applications. Learn how PVC mixing mills contribute to this process, ensuring that the resulting compounds meet the highest standards for quality and performance.

5. Challenges and Solutions: Navigating Issues in PVC Mixing Mills

No technology is without its challenges. Explore common issues faced during the operation of PVC mixing mills and discover effective solutions and best practices to overcome these hurdles.

6. Environmental Impact: Sustainable Practices in PVC Mixing Mills

The rubber industry is increasingly focused on sustainability. Delve into the environmental considerations associated with rubber processing and how PVC mixing mills are adopting sustainable practices to contribute to eco-friendly manufacturing.

7. Case Studies: Success Stories in Rubber Processing with PVC Mixing Mills

Real-world success stories highlight the practical impact of PVC mixing mills. From improved efficiency to enhanced product quality, explore case studies showcasing industries and companies that have reaped the benefits of adopting these transformative machines.

8. Looking Ahead: Future Trends in PVC Mixing Mill Technology

The future holds exciting possibilities for PVC mixing mills. Explore emerging trends and potential developments in technology that could shape the next phase of rubber processing.

Conclusion

PVC mixing mills are the unsung heroes of the rubber industry, driving innovation, efficiency, and sustainability. As technology continues to evolve, these machines will undoubtedly play a crucial role in shaping the future of rubber processing. Stay informed, embrace innovation, and witness the ongoing revolution in PVC mixing mills.