Description

Many industries need to use the blending of solids as part of industrial processing. A ribbon blender mixer is considered as the workhorse of the powder mixing industries, as it effectively blends solids and is also used in heating, cooling, and coating as multipurpose equipment.

This Spiral Ribbon Mixing Blender Machine is made of SUS316 staindless steel material, thanks to its agitator construction that provides a triple mixing action thus ensuring fast efficient blending and homogeneous blending of dry, free-flowing solids ,it is also suitable for plastic, chemical ,food Industries, powder or pellet with additives or color pigment, solid powder with minority liquid additives.

Horizontal Ribbon Blender is a high speed, high capacity batch mixer equipment for the homogeneous blending of dry, powder,Chemicals, Plastic, Pharmaceutical, Paints,food industries and free-flowing solids ,applicable for mixing powder with powder, powder with liquid, and powder with granule etc

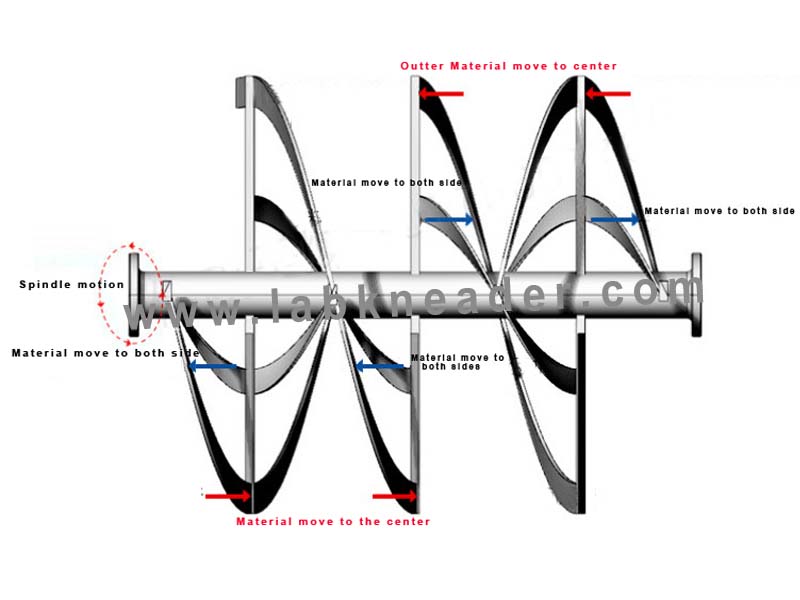

Ribbon Blender Mixer consist of a U-shaped horizontal trough and its core component, a solid agitator shaft attached with spokes that support inner and outer spiral ribbons,designed to move material both inwards and outwards .The external helical ribbons pull product from the sides of the mixer into the middle and the internal ribbons push the product back to the sides. The back-and-forth folding motion of the materials to be blended creates a convective mixing pattern.

Because of the convective mixing pattern of the ribbon blender mixer, its mixing cycle can be designed to be short or fast ,usually ranging from a few minutes up to 20 minutes (it depends to the volume and complexity of the formula). You may think the ribbons run at a very high RPM would be perfect, however this is not so. The ribbon agitators typically run no faster then 300 feet/min tip speed so that the material can be blended and mixed well.

The ribbons are specially designed to have some distancing between the walls of the mixer. In some instances,thus the mixing capacity in the U trough is usually approximately 70 to 80% of total vessel volume, because of 2 factors: (1) adequate space for material flow on the upswing side of the agitator ( 2) complete agitator contact with flowing materials in this container .

Main Structure of Spiral Ribbon Blender

* Machine Body : The supporting structure of the entire equipment.

* Mixing U Trough : The space for holding and mixing materials.

* Agitator : The core component, consisting of inner and outer helical ribbons.

* Feed Inlet : The channel through which materials enter the blender.

* Discharge Outlet : The channel through which mixed materials are discharged.

* Gearmotor: The power source

* Reducer : Adjusts the speed of the agitator.

* Feed Screw Conveyor : Transports materials to the mixing chamber.

* Discharge Screw Conveyor : Transports mixed materials out of the blender.

Technical Specification of Ribbon Blender Mixer

| Model | Power | Speed | Chamber Vol. | Capacity | Shape size | Weight |

| (kw) | (rpm) | (L) | (L) | (mm) | (kg) | |

| SMPRM -0.1 | 3 | 42 | 100 | 30~80 | 1500*500*700 | 400 |

| SMPRM -0.3 | 5.5 | 42 | 300 | 90~240 | 1950*700*1050 | 800 |

| SMPRM-0.5 | 7.5 | 42 | 500 | 150~400 | 2500*800*1350 | 900 |

| SMPRM -1 | 11 | 42 | 1000 | 300~800 | 2800*1000*1450 | 1700 |

| SMPRM -2 | 15 | 33 | 2000 | 600~1600 | 3350*1200*1700 | 2000 |

| SMPRM -3 | 18.5 | 33 | 3000 | 900~2400 | 3750*1300*1800 | 3100 |

| SMPRM -4 | 22 | 32 | 4000 | 1200~3200 | 4150*1400*1900 | 3900 |

| SMPRM -5 | 30 | 32 | 5000 | 1500~4000 | 4300*1500*2000 | 4500 |

| SMPRM-6 | 37 | 32 | 6000 | 1800~4800 | 4500*1750*2100 | 6000 |

| SMPRM -8 | 45 | 28 | 8000 | 2400~6400 | 5100*1850*2200 | 7000 |

| SMPRM -10 | 55 | 28 | 10000 | 3000~8000 | 5600*1950*2350 | 8000 |

| SMPRM-12 | 55 | 28 | 12000 | 3600~9600 | 6550*2100*2500 | 9000 |

Type of Blade

Helical Ribbon Blade

It is the most common blade style, the inclined blades extending to the wall of U shape trough move the material in one direction, while the inner inclined blades move the material in the opposite direction, it is widely applicable, more suitable for powder, free flowing, crumbly, granular, low viscous materials. Usually the mixing process can be finished in 5-10 minutes.

Enhanced Paddle Blade

The paddle mixing blade consist of a shaft with many radial arms. The paddle with the blade has better efficient mixing efficiency and it is suitable for mixing materials with low fluidity or high viscosity. Usually this blade is made of SUS 304 or SUS316 stainless steel to improve the wear resistance of the blade.

Plow Shape Blade

When used in a standard or low speed U-shaped horizontal blender mixer, the pear component can meet with your needs for “folding” the material. Although the pear blade will effectively mix the material over time, it is mainly used to “gently” mix the material for chemical reactions or for heating, drying, wetting, etc.

Benefits of Choosing a Simptek Ribbon Blender Mixer

1. With robust designs, customizable features and user-friendly operation

2. Made from high-quality stainless steel and carbon steel

3. Bearing mounted on lanterns outside of mixing container to avoid contamination.

4. Feeding through a hopper mounted on top of blender.

5. Special designed double ribbon agitator benefit to excellent blending and distribution.

6. Low speed mixing with lower heat generated, suitable heat-sensitive product and low temperature processes.

7. Totally open lid for cleaning easily. Shaft sealing by purging air to prevent fine powder going into bearing.

How Does a Ribbon Blender Mixer Work?

The Ribbon blending mixer is based on a proven agitator construction that provides a triple mixing action thus ensuring fast efficient blending.

When working ,the external helical ribbons pull product from the sides of the mixer into the middle and the internal ribbons push the product back to the sides. The back-and-forth folding motion of the materials to be blended creates a convective mixing pattern.

Mixing Process:The mixing process begins when the materials are loaded into the mixer container. Once the container is loaded, the motor is turned on and the paddles begin to rotate.The shaft is driven by a motor that is actually connect with paddles ,which are precisely pitched to move material both radially and axially in opposite directions.

Mixing Time: The amount of mixing time rely on the type and volume of materials being mixed. However, most paddle mixers have a set mixing time that can be adjusted depending on the application.

Application of Spiral Ribbon Blender Mixer

The construction industry uses a ribbon blender to blend cement, mortar and other construction materials to ensure a uniform mixture suitable for construction.

These ribbon blender mixer are widely used in stirring and mixing powder and powder, powder and liquid, compound fertilizer, dyes, pigments etc ,here is just some example as follows:

* Pharmaceutical Industries: it is used to blend active ingredients and additives to ensure a consistent drug formulation.

* Food Industries: uses ribbon blending machines to blend spices, flour and other ingredients to achieve flavour and texture.

* Chemical Industries: it is used to combine powder, granules and other raw materials to ensure product quality,including Adhesives, Carbon Black, Dyestuff, Electrode Mass, Fly Ashes, Fungicides, Peat Moss Mixes, Pesticides, Pharmaceuticals, Pigments, Plastic Additives, Resins, Solid Lubricants

* Foods: Baking Powder, Cheese Spread Ingredients, Confections, Deep-frying Batter Mixes, Drink Mixes, Frozen Fruits, Fruit Pulps, Herbs, Instant Soups, Muesli, Potato Flakes, Salads, Snack Foods, Stock Cube Mixes, Table Salt, Tobacco, Waffle Filling.

*Nutrition: Enzymes, Lecithin Powder, Mineral Substances, Nutrition Supplements, Protein, Sports Nutrition, Vitamin Mixes, Whey Powder.

*Animal Care: Animal Feeds, Chicken Fattening Feed, Fish Foods, Mineral Feed, Pet Foods, Poultry Feed, Rabbit Feed, Veterinary Medicine.

*Cosmetics: Coloring Powder, Dispersing Agent, Kaolin Clay, Mask Powder, Mica Flour, Surface Active Agent, Talcum Powder, Titanium Dioxide.

*Daily Care: Aromas, Cat Box Litter, Cleansers, Detergents, Potpourri.

*Building Materials: Decorative Paste Coatings, Dry Mortar Mixes, Fibre Cement Cladding, Gypsum, Joint Compounds, Thermal Insulation Composite.

Operation of Ribbon Blender Mixer

1.Wear you protective tools including goggles, safety boots ear protection and glove.

2. Ensure all guards and covers are in place before using the mixer machine.

3. Ensure the paddles are rotating before adding the material to be mixed. Stop the paddles before dumping the

mix.

4. Do not move the paddle mixer machine while the drum is full or while the engine is running.

5. Do not attempt to repair or service the blending mixer machine while it is running.

6. Stop the engine if leaving the paddle mixer machine unattended.

7. The exhaust and other parts get very hot in use; Be careful not to burn yourself.

8. You must dispose of the waste from unused mixes properly; follow the instructions on the

manufacturer’s container or leaflet.

9. You must clean the paddle mixer and especially the drum and paddles as soon as you have finished work before the mix goes hard

Choose Your Agitator: Double Ribbon or Paddle-Ribbon?

Double-Ribbon Agitator

The double-ribbon blender agitator is valued for its thorough mixing. It consists of an inner and an outer ribbon providing counter-directional flow while keeping the product in constant motion throughout the vessel. The inner ribbons move materials toward the ends of the ribbon blender whereas the outer ribbons move material back toward the center discharge of the ribbon blender.

Paddle-Ribbon Agitator

The paddle-ribbon agitator combines inner ribbons with outer paddles. The paddle-ribbon blender is especially well suited for fragile, heat sensitive products. While maintaining counter-directional flow, the outer paddles minimize pinch points at the wall thus introducing less frictional heat than a continuous outer ribbon.

Reviews

There are no reviews yet.