Description

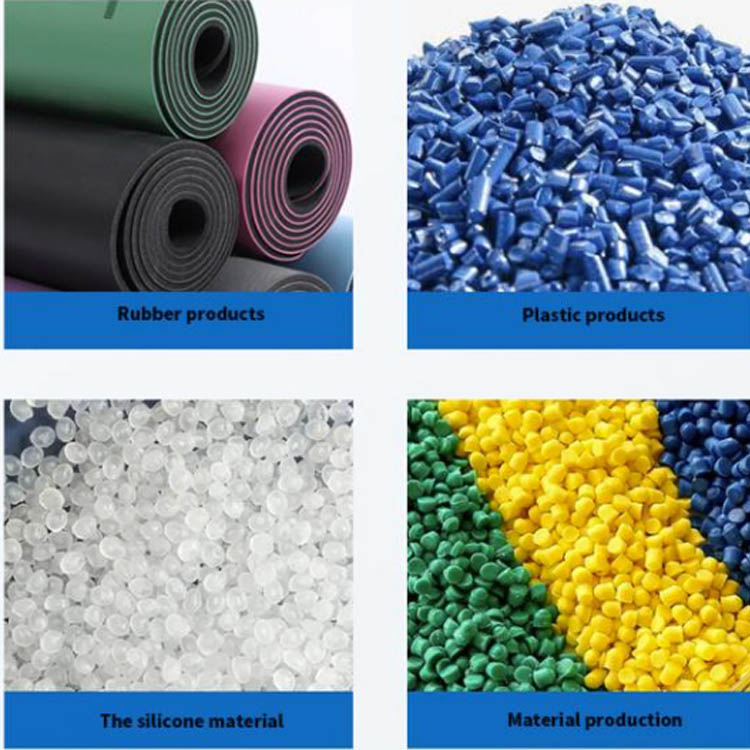

The two roll rubber mill is a machine for masticating and kneading plastic ,PVC Silicone ,natural rubber,synthetic rubber , EVA or PVC pellets .

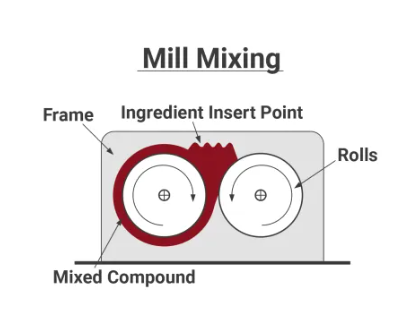

Basically two roller laboratory rubber mixing mills consist of two rolls, bearing, gap adjusting device, electric control system, safety device, etc. Its roller are made from vanadium titanium alloy chilled cast iron,its hardness(HRC) can reach up to 50-60, its surface is hard wear-resisting, durable,the two rolls of the rolling mill rotate in the opposite direction towards each other ,they run at different speeds ,the roller lumen finish machining,which create shearing forces that mix and refine the rubber material,so that the roller body cooling quickly and evenly when processing.

These opposed stainless steel rolls rotate in opposite directions towards each other ,they run at different speeds ,the roller lumen finish machining,so that the roller body cooling quickly and evenly when processing.

Would you like to increase the safety standards of your production? Then contact us now ! We are experts concerning safety of mixing mills and other rubber mixing machines for processing rubber , plastics and polymer, including rolls calanders, hydraulic presses, banbury intensive mixers and more. Since we have been in rubber processing machinery bussiness for many years , we know the individual challenges of this kind of machinery and the specific needs of machine operators.

Are you interested in avoiding money- and time consuming research on specific safety regulations? We are happy to assist you concerning individual, specific, and practical safety consulting conrresponding to state of the art technology.

Key Features

1. Size and Capacity : The 6inch two roll mixing mill has a 6 inch(160mm) working width and a 12.5inch(320mm) long rolls .It is ideal for small laboratory scale mixing for research & institues

2. Durable Construction :This two rolls mill adopt high-quality material,which allow the laboratory equipment use for a long time and maintance free.

3. Versatile Application :The rubber mixing mill is applicable for rubber ,silicone ,PVC, polymer ,chemical and many other various manufacturing industrials.

4. Efficient Operation : Advanced mechanisms enable smooth ,efficient and safe operation. This can greatly boost your productivity capacity and save much costs .

Steps in the Rubber Mixing Process

1. Introduction of the Polymer

The rubber mixing process begin from the introduction of the polymer, the basic structure of rubber compounding. The choice of polymer material contribute to the foundation for the material’s performance and dictates its inherent characteristics.

2. Sequenced Addition of Ingredients

While the polymer typically has the largest impact on the characteristics, additional ingredients are added would determine its features ,including curing and processing performance, consideration of production cost , hue designation, anti-degradation, and many other . This may be fillers, plasticizers, curing agents, accelerators, etc.

3. Achieving Homogeneity in the Compound

The ultimate goal is to achieve thorough homogeneity. Through well-mixed and blended of all ingredients ,it would create a uniform and consistent rubber compound. A homogeneous rubber compound ensures uniform characteristics throughout production processing, curing and the final application of finished rubber goods. This is achieved by carefully adjusting the several key mixing parameters according to the compound requirements while carefully considering chemical interactions of ingredients. Each rubber compound performs and reacts differently to the process. Therefore , to create a ideal mixture ,it requires an experienced operator execute on each compound’s detailed and exact mixing procedure .

Use & Application

* Rubber Processing : It mixes and refines rubber compounds .It ideally ensures uniformity and better material properies.

* Plastic & Polymer Manufacturing : Blending plastic & polymer is best for getting the right formulas and quality .

* Foorwear Production : Mixing components is vital to making shoes & footwear

* Hot-melt adhesives

* Technical ceramics

* Manufacture of abrasives

* Graphite compounds

* Sealing compounds

* Hard metal compounds

Advantages of Simptek premium two roll mixing mills

*Space-saving and ground-level installation

*Twin-drive with separately adjustable speed / infinitely variable friction

*Modern PLC based on Siemens S7 components with touch panel

*Energy-efficient – potential energy savings of up to 30%

*Low noise level

*Low maintenance and repair costs

*High quality

Why Chose Simptek Kneader?

Simptek specialzies in custom making and supplying high-quality rubber processing machine in China. As one leading professional rubber machine manufacturer , our experienced staffs and professional engineers team ,enable us to provide fast and efficient serve to our valued customers . We also offer servicing and maintenance services ,manpower support and annual maintenance contracts .

Simptek Machine is a leading manufacturer and supplier of rubber kneaders, dedicated to delivering high-quality rubber processing equipment globally.

Trust Simptek for all of your needs . They offer unmatched quality ,reliability ,and great serve . Contact us today to see our offerings . They will help your industrial operations reach new heights !

Working in different safety commissions and committees we are always at the latest state of knowledge concerning machine-specific rules and machinery directives.

We at Simptek provide consultancy regarding the options of safety retrofitting to implement the necessary safety measures for almost all types of machinery for processing rubber and plastics like mixing mills, mould carriers, presses, calenders, internal mixers and others. Moreover, we offer high quality and reliable retrofit kits (with or without installation) for all mixing mill types and sizes as well as safety cages for laboratory mixing mills. Thereby, you bring the safety equipment of your machines up to the required level and reestablish the protection of your employees.

For more information about how you can retrofit your machines with support from Simptek, please contact our knowledgeable sales team.

Reviews

There are no reviews yet.