* Short mixing time ,high efficiency production and good quality rubber compound

* An automatic temperature and time control system to provide a 100% mixing result.

* Each batch need about 6~10minutes to output equivalent for 2 open mixing mill

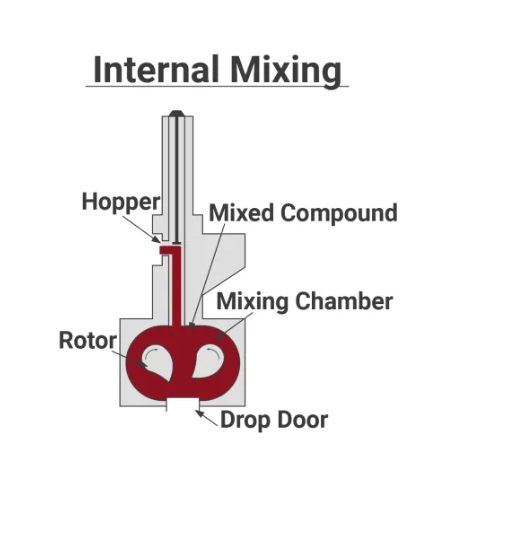

* Pressurized and sealed mixing chamber to provide high mixing performance and prevent the environment.

* Intensive mixers for research, development, and small production

*Easy installation, operation and maintenance, lower the running cost.

* Easy to clean chamber and changing colors

* Used for plasticizing and mixing of natural rubber, synthetic rubber, reclaimed rubber and plastics

Welcome to our Simptek Limited

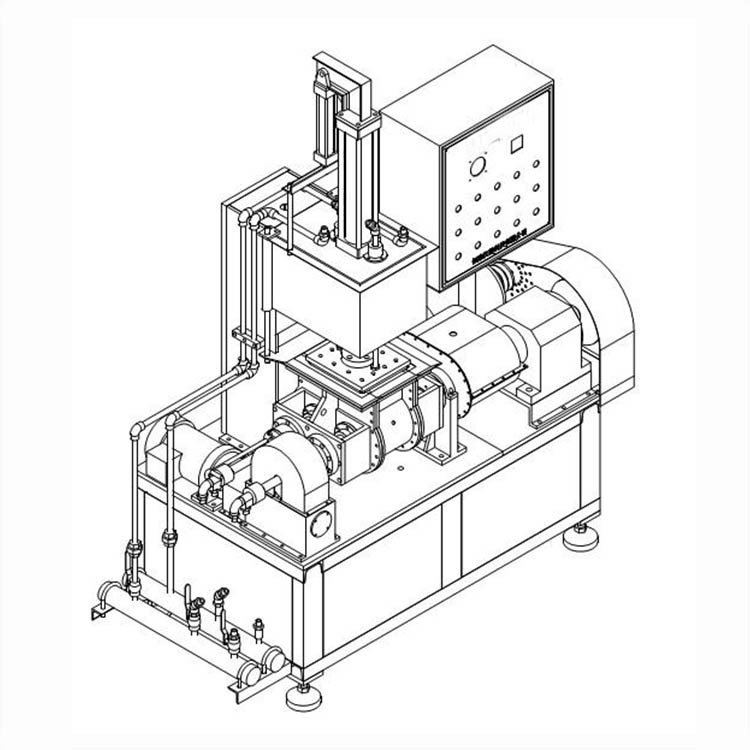

PLC Controlled Rubber Plastic Dispersion Kneader SPML-015

Rubber Kneader Machine Manufacturer | Laboratory Dispersion Kneader | Intensive Banbury Mixer

Reviews

There are no reviews yet.