Description

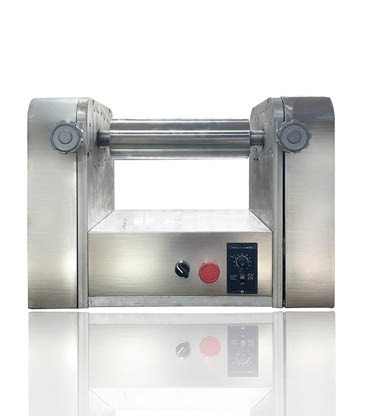

This benchtop laboratory two roll mill is also called two roll open mill, two roll rubber mixer ,it is a compact electric mixing equipment which is used to shear and compress polymers material ,like rubber ,silcone ,plastic ,elastorner ,it is suitable suitable for plasticizing and dispersing for color master batch, PVC, EVA ,plastic and pigment.

The laboratory mixing machine consists of roll, bearing, gap adjusting device, electric control system, safety device, etc. it is important equipment for formula development, small batch testing or sample production , color matching . These lab mixing mill are successfully used for research, development and quality control all over the world.

This 3inch multipurpose bench-top laboratory two roll mixing mill mainly consist of machine base ,frame ,front and rear rollers , distance adjustment device ,driving device ,transmission device ,heating device and emergency stopping devices , it is specially designed for dry, wet and cryogenic grinding of small volumes , It is specially used to mix and homogenize powders and other low-viscosity elastomers material ,including rubber ,plastic,polymer ,chemical ,silicone, pigment,masterbatch,thermoplastic elastomers,resin,fillers and other auxiliary elements.

Additional agents & additives would be need to added during the mixing process under the action of intensive shearing and squeezing ,so that get the desired compound material . The resulting compound material can further be used for color matching comparisons ,physical tests ,chemical tests .formula development etc.

This compact bench-top laboratory mixing mills are widely used for small-batch formula testing ,contrast and quality control for plastic polymer rubber industries for research laboratories purpose.

Different from other larger laboratory mixing equipment ,this mini lab two roll mixing mill feature a smaller diamater of the rollers (about 70mm diameter), it takes less space and comsume lower energy, it can be allowed to put on your counter ,desktop or tabletop for material processing .

The two same size rollers are arranged parallel to the horizontal opposed direction, they are driven by one single reduction motor and the power is transmitted through chains ,sprockets and gear pairs .

These two roller of this open mixing mill are heated by electric and cooled to specific temperatures to facilitate the mixing process. The rollers are typically made of high-quality steel and are coated with a layer of rubber or plastic to prevent sticking and improve mixing efficiency.

Simptek Machine is one of the very most renowned two roll mill manufacturers and ensures the production of good quality products ideal for varied industrial applications.

Technique Parameter

| Model | SPKL-002B60 | SPKL-002B100 |

| Roll Diameter | 60mm | 100mm |

| Roll Hardness | 50-60HRC | |

| Roll Surface Treatmente | Mirror polished and chromed plated | |

| Roll Nip | 0.1-4mm,adjustable | 0.1-6mm,adjustable |

| Friction Ratio | 1.25:1 or customized | |

| Roll Heating Mode | None/ electrical heating/ oil heating | |

| Roll Temperature Range | About 250 ℃ | |

| Temperature Controller | PID | |

| Temperature Uniformity | 1.5℃ | |

| Safety Features | One button emergency stops (with reversing function) | |

| Motor Power | 750W | |

| Power Supply | AC380/110V | |

| Dimensions(L× W× H) | 640x350x320mm | 680x350x450mm |

| Weight | Approx 65kgs | Approx 75kgs |

Nip Gap adjustment is Motor Driven

Operating Panel Combination of touch screen and PLC-control allows comfortable operation of the machine

Application of Two Roll Mills

*PVC powder mixing and colour sampling

*Polymer milling mixing

*Plastics formulation mixing test

*Rubber mixing test

*Material development, material testing, quality control, education

*Raw rubber ,Synthetic rubber ,Thermoplastics or EVA with chemicals

*Polymer like LDPE, HDPE, PP, PVC, PS, ABS, HIPS, Natural Rubber, EVA etc. can be tested.

The Rubber Mixing Mill Serves Many Function Across Various Industries

1. Rubber Processing : Perfect for mixing ,keading ,and blending rubber compounds ,which ensure uniformity and consistency in the final product.

2. Manufacturing : Ideal for the production of rubber sheets ,belts ,tires ,and other rubber-based product with precise specifications and quality control.

3. Research and Development : Facilities experimentation and testing of new rubber formulations ,which enable innovation and improvement in product performance .

4. Quality Assurance : We guarantee the integrity of rubber compounds by thoroughly mixing ingredients ,eliminating air bubbles , and dispersing additives evenly .

5. Customization : We offer flexibility in adjusting mixing parameters to satisfy your special requirements for different rubber , plastic ,silicone formulations and applications .

Benefits of Chosing Simptek Rubber Mills

* Enhanced productivity : Increase your production efficiency with this high-capacity kneader, reducing processing time and enhancing overall output.

* Consistent Quality :Achieve unparalleled consistency in rubber compounds ,satisfying the most stringent quality standards with every batch.

* Versatility : Suitable for a wide range of rubber formulations and applications , also applied for diverse industry needs .

* Reliable Performance : Experience reliable and precise mixing ,ensuring uniform dispersion and superior product quality .

Reviews

There are no reviews yet.