Description

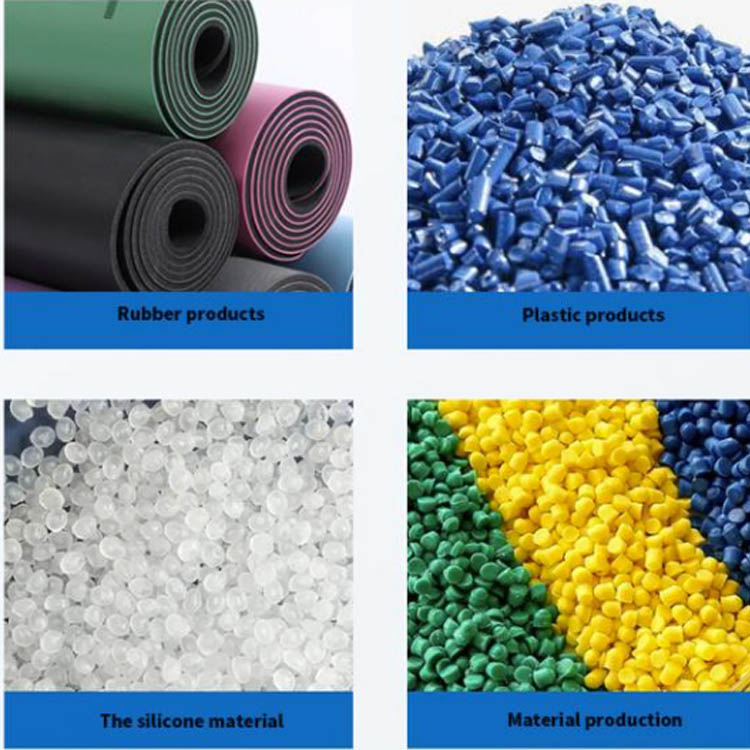

Two Roll Rubber Open Mixing Mill is an amazing combination of innovation and technology that serves the purpose of mixing and kneading various forms of plastics and rubbers. The products industry of plastics and rubbers is raw rubber, synthetic rubber, thermoplastics, polymers, PVCs, EVA or Color masterbatch. It is highly usable in the industry that deals with plastics and rubbers.

The machine comprises rigid chrome plates that are mirror polished and anti-corrosive. The plates are highly resistant to the high temperatures, thus allowing the machine to work in a very systemized way as the material that is the result of the processing of this two-roll mixing mill is further used to feed calendars, hot presses, and various other kinds of machines that are used to manufacture and process multiple types of rubbers and rubbers and plastics.

This two-roll rubber cracker mill is based upon the option of the two-way heating model that involves electric heating or oil heating that is done either with the help of a water-cooling system, or it can be done without the use of a water-cooling system as well.

Such Rubber crumb/reclaim, Rubber Refiner Mill are widely used in new tyres/tubes, devalcanisation for low-tech pressed or extruded rubber products, tread rubbers, belting, battery containers, molded item, commercial flooring, traffic control products and plenty more.

This incredible piece of technology also allows the adjustment of the two rolls that can be fixed with a constant ratio. To ensure the user’s safety, they come with an option of an emergency device that ensures the user’s safety.

The Basic Components of a Rubber Mixing Mill Include

A Rubber mixing mill is indispensable in various industries where precision and quality are paramount, such as in the production of automotive tires,footwear, belts, hoses, and gasketsspong and other rubber silicone industrial etc.

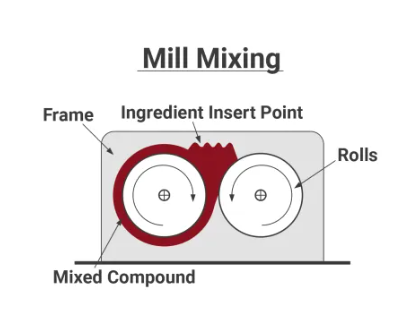

* Roller System: Two or more steel rollers rotate in opposite directions to mix and knead the rubber and additives.

* Heated Rollers: For curing the rubber material during the mixing process.

* Control System: For controlling the speed , temperature, and pressure of rolls during mixing process.

Key Features

1. Size and Capacity : The 6inch two roll mixing mill has a 6 inch(160mm) working width and a 12.5inch(320mm) long rolls .It is ideal for small laboratory scale mixing for research & institues

2. Durable Construction :This two rolls mill adopt high-quality material,which allow the laboratory equipment use for a long time and maintance free.

3. Versatile Application :The rubber mixing mill is applicable for rubber ,silicone ,PVC, polymer ,chemical and many other various manufacturing industrials.

4. Efficient Operation : Advanced mechanisms enable smooth ,efficient and safe operation. This can greatly boost your productivity capacity and save much costs .

Steps in the Rubber Mixing Process

1. Introduction of the Polymer

The rubber mixing process begin from the introduction of the polymer, the basic structure of rubber compounding. The choice of polymer material contribute to the foundation for the material’s performance and dictates its inherent characteristics.

2. Sequenced Addition of Ingredients

While the polymer typically has the largest impact on the characteristics, additional ingredients are added would determine its features ,including curing and processing performance, consideration of production cost , hue designation, anti-degradation, and many other . This may be fillers, plasticizers, curing agents, accelerators, etc.

3. Achieving Homogeneity in the Compound

The ultimate goal is to achieve thorough homogeneity. Through well-mixed and blended of all ingredients ,it would create a uniform and consistent rubber compound. A homogeneous rubber compound ensures uniform characteristics throughout production processing, curing and the final application of finished rubber goods. This is achieved by carefully adjusting the several key mixing parameters according to the compound requirements while carefully considering chemical interactions of ingredients. Each rubber compound performs and reacts differently to the process. Therefore , to create a ideal mixture ,it requires an experienced operator execute on each compound’s detailed and exact mixing procedure .

Safety Feature

*Emergency brakes with limit switch

*Emergency brakes Chest bar with reverse INCH facility provided

*Emergency brakes Provided on both sides to stop machine in ⅓rd Revolution of Front Roll

*Auto reversible control panel

*Hydraulic & Electromagnetic Thruster Brakes

Applications of Rubber Mixing Mills

* Foorwear Production : Mixing components is vital to making shoes & footwear

* Hot-melt adhesives

* Technical ceramics

* Manufacture of abrasives

* Graphite compounds

* Sealing compounds

* Hard metal compounds

*Tire Manufacturing: In tire production, the laboratory dispersion kneaders are essential for mixing natural or synthetic rubber with various additives, such as fillers, plasticizers, and vulcanizing agents. Our equipment precisely controls temperature and pressure during kneading, enhancing tire grip and wear resistance.

*Rubber Product Compounding: Dispersion kneaders are widely used to produce rubber compounds like sealants, silicone rubber ,gaskets, hoses, and conveyor belts. Efficient mixing and material distribution enhance the physical properties of rubber, such as strength, elasticity, and chemical resistance, making our equipment suitable for the automotive, aerospace, and construction industries.

*Polymer and Chemical Processing: In the polymer and chemical industries, this laboratory dispersion kneader produce rubber and plastic products such as films, sheets, adhesives, and Pharmaceutical industry.

Advantages of Simptek Premium Two Roll Mixing Mills

*Space-saving and ground-level installation

*Twin-drive with separately adjustable speed / infinitely variable friction

*Modern PLC based on Siemens S7 components with touch panel

*Energy-efficient – potential energy savings of up to 30%

*Low noise level

*Low maintenance and repair costs

*High quality

Operational Considerations

Manual Operation: The operation of this two-roll mills often requires manual operation, such as cutting, folding, and rolling the material on the front roll. This ensures the homogeneity of the mixture but it would be strongly to operate by skilled operators.

Safety Systems: The two-roll mixing mills are usually equipped with safety systems to ensure the safety of operator, providing maximum comfort and reducing the risk of accidents during operation.

Reviews

There are no reviews yet.