* Short mixing time ,high efficiency production and good quality rubber compound

* Low labor intensity and low energy consumption.

* An automatic temperature and time control system to provide a 100% mixing result.

* Each batch need about 6~10minutes to output equivalent for 2 open mixing mill

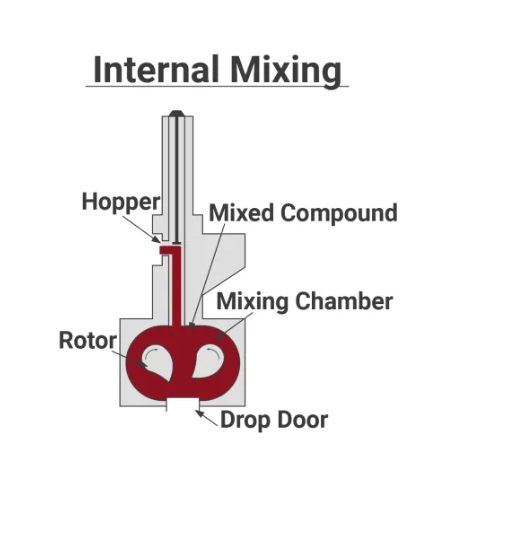

* Pressurized and sealed mixing chamber to provide high mixing performance and prevent the environment.

* Pressurized sealed mixing chamber to ensure the quality of the mixture outside and prevent environmental pollution

* Fillers can be mixed with a variety of materials quickly and easily

* Compounds are produced with exceptional uniformity

* Excellent results even with hard-to-mix materials

* Easy to clean chamber and changing colors

* Suitable for stiring, kneading and dispersion of all kinds of chemical raw materials

* Easy for operation ,easy for changing color ,high quality processed products

Welcome to our Simptek Limited

Lab Plastic Kneader Mixer Machine SPML-014

Lab Dispersion Kneader | Rubber Mixing Mills | Plastic Processing Machine

Reviews

There are no reviews yet.