Description

Laboratory Rubber Mixing Machine, also known as open double-roll refiners, are specialized in mixing rubber compounds in the rubber and plastics processing industry ,it is enginered to provide unmatched performance for masticating and kneading natural rubber, synthetic rubber, EVA, or PVC pellets with various chemical materials, This two roll mill machine is mainly used for plastic, hot mill, and mixing mill of natural and synthetic rubber for rubber product factory, specially used for learning institutes and laboratories with smaller batch size preferences.

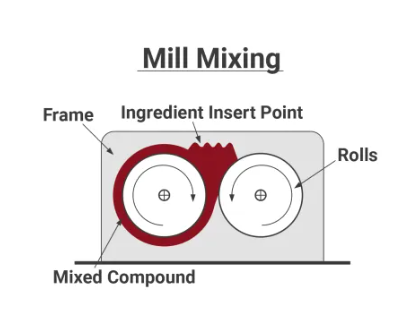

This two rolls rubber mixing machine mainly comprise of base, frame, rollers, transmission system, lubrication device, heating and cooling device, roll gap adjustment device, safety braking device, motor, speed reducer etc. The speed of rollers is controlled and adjusted by reducer driven by transmission , which is conducted by the main motor.

We have two opition for you ,either two roller by one transmission or each transmission control the speed for each roller respectively .

Our PVC polymer open mixing mill equipment can be customized in different capacity and confirgurations as per your specific needs . It is widely used for small-batch formula testing ,contrast ,and quality control in polymer material research and development laboratories .

Technical Parameters

| Item | SM–160 | SM–250 | SM–360 | SM–400 | SM–450 | SM–550 | SM–660 | SM–710 | |

| Roll diameter | mm | 160 | 250 | 360 | 400 | 450 | 550 | 660 | 710 |

| Roll working length | 320 | 620 | 900 | 1000 | 1200 | 1500 | 2130 | 2200 | |

| Front roll linear speed | r/min | 9 | 16.3 | 16.7 | 19.3 | 21.8 | 22.5 | 28 | 31.9 |

| Speed ratio of rolls | 01:01.4 | 01:01.1 | 01:01.3 | 01:01.3 | 01:01.3 | 01:01.2 | 01:01.2 | 01:01.5 | |

| Max roll space | mm | 4.5 | 8 | 10 | 10 | 12 | 16 | 0.5-15 | 0.5-15 |

| Compound feeding capacity | kg | 1月2日 | 10月15日 | 20-25 | 18-35 | 50 | 50-65 | 165 | 190 |

| Motor power | kW | 5.5 | 18.5 | 30 | 45 | 55 | 110 | 240 | 280 |

| Dimensions(L× W× H) | |||||||||

| L | mm | 1133 | 2722 | 4200 | 4920 | 5405 | 6646 | 7280 | 8185 |

| W | mm | 920 | 1115 | 1780 | 1780 | 1740 | 2736 | 3400 | 3910 |

| H | mm | 1394 | 1345 | 1760 | 1800 | 1790 | 2105 | 2530 | 2270 |

| Gross weight | T | ~2 | ~3.2 | ~6.5 | ~8 | ~11.4 | ~22 | ~49 | ~51 |

Nip Gap adjustment is Motor Driven

Operating Panel Combination of touch screen and PLC-control allows comfortable operation of the machine

Steps in the Rubber Mixing Process

1. Introduction of the Polymer

The rubber mixing process begin from the introduction of the polymer, the basic structure of rubber compounding. The choice of polymer material contribute to the foundation for the material’s performance and dictates its inherent characteristics.

2. Sequenced Addition of Ingredients

While the polymer typically has the largest impact on the characteristics, additional ingredients are added would determine its features ,including curing and processing performance, consideration of production cost , hue designation, anti-degradation, and many other . This may be fillers, plasticizers, curing agents, accelerators, etc.

3. Achieving Homogeneity in the Compound

The ultimate goal is to achieve thorough homogeneity. Through well-mixed and blended of all ingredients ,it would create a uniform and consistent rubber compound. A homogeneous rubber compound ensures uniform characteristics throughout production processing, curing and the final application of finished rubber goods. This is achieved by carefully adjusting the several key mixing parameters according to the compound requirements while carefully considering chemical interactions of ingredients. Each rubber compound performs and reacts differently to the process. Therefore , to create a ideal mixture ,it requires an experienced operator execute on each compound’s detailed and exact mixing procedure .

Application of Two Roll Mills

*PVC powder mixing and colour sampling

*Polymer milling mixing

*Plastics formulation mixing test

*Rubber mixing test

*Crushing,mixing and pressing of recycled rubber

*Recycling and processing of waste rubber materials

*Material development, material testing, quality control, education

*Raw rubber ,Synthetic rubber ,Thermoplastics or EVA with chemicals

*Polymer like LDPE, HDPE, PP, PVC, PS, ABS, HIPS, Natural Rubber, EVA etc. can be tested.

*PVC, and color master batch

The Rubber Mixing Mill Serves Many Function Across Various Industries

1. Rubber Processing : Perfect for mixing ,keading ,and blending rubber compounds ,which ensure uniformity and consistency in the final product.

2. Manufacturing : Ideal for the production of rubber sheets ,belts ,tires ,and other rubber-based product with precise specifications and quality control.

3. Research and Development : Facilities experimentation and testing of new rubber formulations ,which enable innovation and improvement in product performance .

4. Quality Assurance : We guarantee the integrity of rubber compounds by thoroughly mixing ingredients ,eliminating air bubbles , and dispersing additives evenly .

5. Customization : We offer flexibility in adjusting mixing parameters to satisfy your special requirements for different rubber , plastic ,silicone formulations and applications .

Benefits of Chosing Simptek Rubber Mills

* Enhanced productivity : Increase your production efficiency with this high-capacity kneader, reducing processing time and enhancing overall output.

* Consistent Quality :Achieve unparalleled consistency in rubber compounds ,satisfying the most stringent quality standards with every batch.

* Versatility : Suitable for a wide range of rubber formulations and applications , also applied for diverse industry needs .

* Reliable Performance : Experience reliable and precise mixing ,ensuring uniform dispersion and superior product quality

Reviews

There are no reviews yet.