Description

A plastic extruder, also called an extrusion machine, is a machine that is used to produce polymer products of various shapes. The plastsic raw plastic material are fed from the hopper of extruding machine and then passed through a mold under pressure to turn them into the desired final shape, either in granules ,tape or profile etc .

The lab twin screw extruder is used for minimum capacity 2kg per hour ,it is mainly used for laboratory in unversity & institute , it is mainly used for experiment that testing the melting temperature and chemical properties of the thermo-plastic such as PVC, PPR, PE , PP , HDPE, LDPE, masterbatch and other Polymer material.

This twin screw extruder come with PLC system,which feature high-level touch screen panels for manual or automatic operations. Its operating paramete are displayed in the screen for better control and operation.

Our twin screw extruder are widely used for High Concentration Color Masterbatch (including PE,ABS,PS,EVA,PET,PP + color +additives, etc),Filler Masterbatch, Additive Masterbatch, Biodegradable Plastic, Cable Compounding, Engineering Plastics Reinforcing (GF),

PVC Compounding, Polyolefin Compounding, Reacting Direct Extrusion, Thermoplastic Elastomers,

PET pelletizing and other plastic such as PP, PA, PBT, ABS, AS, POM, PPS, PET, etc, Ploymer compounding such as PC+ABS, PA+ABS,CPE+ABS,PP+EPDM,PA+EPDM, PA+SBS, etc

Main Components of Extruder Machine

The twin screw plastic extruding machine is one of the advanced technologies in the plastic polymer production industries, which are used to produce all kinds of plastic polymer products with different shapes and sizes. This device mainly consists of several main components as follows:

Hopper

The raw material are fed from this entry,also named as feeding funnel of extruding machine and then pushed to next process of this extrusion machine.

Screw

The spiral screw may be made of different materials such as stainless steel, aluminum or plastic. This component is mainly used to transfer the raw materials from the feeding funnel to the front and heat and melt the plastic materials.

Barrel

It is the part where screw , this barrel is usually made of stainless steel material , it has several heat channels for heating the raw materials. Basically , the barrel’s design, including its length and diameter, plays a significant role in the quality of the extrusion process.

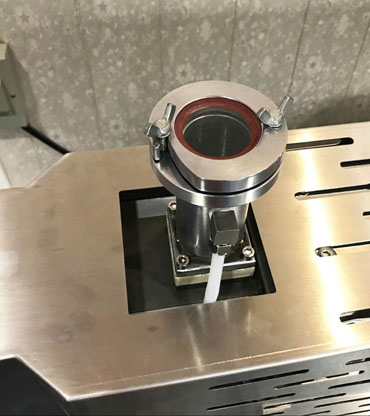

Die

The die mold is . Just because of this die mold , the molten material passing through it and create the desired shape. The dies mold may be made of different materials such as stainless steel, polycarbonate, or plastic,it is located at the end of the extruder machine.

Electric motor

The electric motor provides the driving force of the screw. Electric motors are usually of the three-phase type and have high revolutions.

Specification

| Model | Diameter | Max. Speed | Motor | Length of Screw (L/D) | Output |

| (mm) | (rpm) | (kW) | (kg/hr) | ||

| SMP20 | 20 | 93 | 3 | 8-32 | 5-10 |

| SMP65 | 65 | 93 | 30 | 8-32 | 80-100 |

| SMP120 | 120 | 93 | 160 | 8-32 | 500-600 |

| SMP150 | 150 | 93 | 200 | 8-32 | 700-900 |

| SMP180 | 180 | 93 | 280 | 8-32 | 800-1300 |

| SMP200 | 200 | 93 | 355 | 8-32 | 1200-1500 |

| SMP240 | 240 | 93 | 455 | 8-32 | 1500-2000 |

| SMP300 | 300 | 70 | 600 | 8-32 | 2500~3000 |

| SMP400 | 400 | 70 | 1000 | 8-32 | 4000~5000 |

| SMP500 | 500 | 70 | 1300 | 8-32 | 5000~7000 |

Usage of Laboratory Extruders

Laboratory extruder machine are small scale production extruders with a variety of important uses:

*Small Batch Production

Laboratory extruder machine are ideal to provide the delivery and response time for low volume production.

*Product Development

This laboratory extrusion equipment also can be vital for a manufacturing company to develop new products and test new extrusion processes.

*Material Research and Testing

This lab extruder machine can be also used to test for new materials or different formulations before mass production.

*Quality Control

It is crucial to test the quality from several samples on a large quantity of goods ,so that ensure the constant improvement and optimization for ongoing research and development for final products.

*Education and Training

The versatile small batch table top Lab extruders can are the mostly ideal laboratory equipment for hands-on experience due to its fast changeover capability, maximize training time.

Application of Extruder Machine

Our laboratory twin screw extruder are applicable for compounding, direct extrusion, degassing (devolatilization) and reaction extrusion.

They can be used to stimulate the continuous extrusion process for batch samples, new material research, new process development and small quantity production.

The extruder machine are also applicable for the following material :

*Polymer melting, plasticizing and extruding

*Optimization of processing parameters

*Producingcast film, sheet and tube/pipe with corresponding dies.

*Optional melt pump or static mixing device can be used to improve plasticization effect

*Manual screen changer is optional to improve the purity and quality of melt.

* Filler Masterbatch

* Color Masterbatch

* Additive Masterbatch

* Biodegradable Plastic

* Cable Compounding

* Engineering Plastics

* Reinforcing (GF)

* PVC Compounding

* Polyolefin Compounding

* Reacting Direct Extrusion

* Thermoplastic Elastomers

* PET pelletizing and other

* plastic such as PE, XLPE, WPC etc

Reviews

There are no reviews yet.