* Laboratory dispersion kneader machine with PLC control

* Short mixing time ,high efficiency production

* High torque ,low noise,and a farced lubrication circulation system

* An automatic temperature and time control system to provide a 100% mixing result

* Easy to clean chamber and changing colors

* In 6~10minutes/batch of output equivalent to 2 units of open mixing mill.

* Semi- Automatic, Automatic & Fully Automatic PLC & HMI Base operating.

*Applicable to rubber, plastic and chemical industry,including EVA., rubber, TPR, Hoses ,tires

Welcome to our Simptek Limited

Lab Dispersion Kneader Machine SPML-012

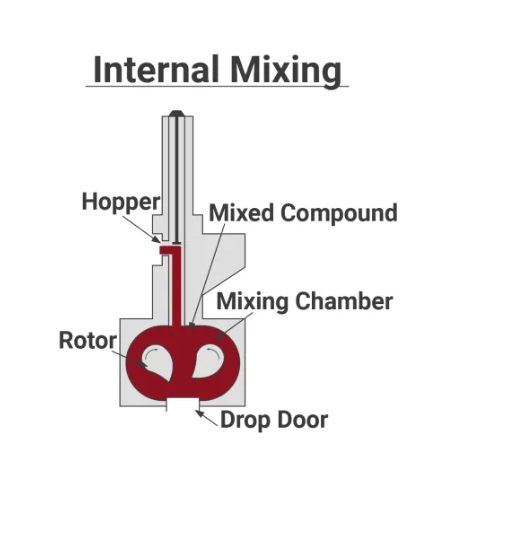

Lab Rubber Kneader | Internal Mixer | Banbury Machine

Reviews

There are no reviews yet.