* Small Laboratory dispersion kneader mixer machine

* Designed for small-batch processing and a wide variety of contemporary mixing needs

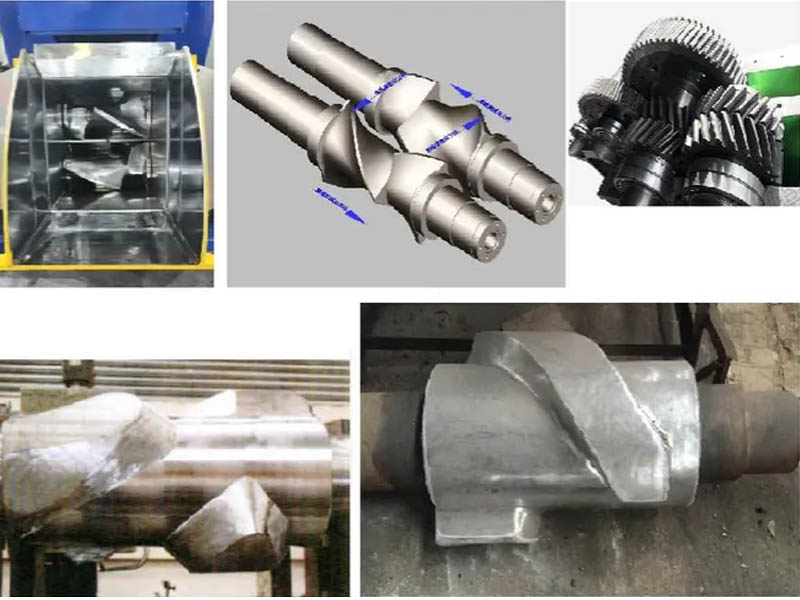

* Rotor:Abrasion resistant hard alloy,Plated with hard chromium.

* Temperature and time control system:Imported PLC control system to provide a 100% mixing effect.

* Easy to operate and color changing

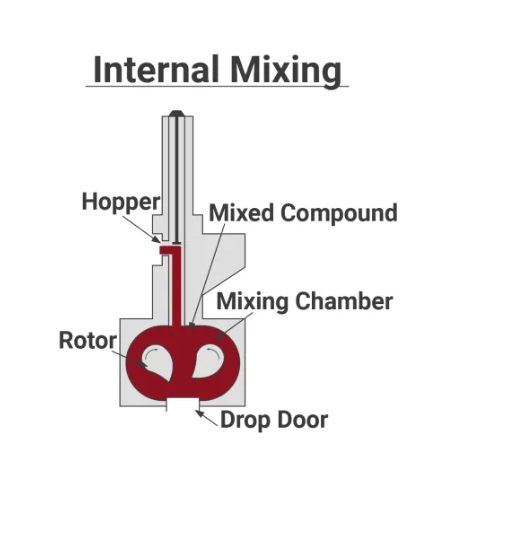

* The mixing chamber is constructed with heat resistance, weather resistannce and anti-corrsive

* Adopt pressed mixer chamber, ensuring the quality of mixing to get the best efficiency

* Used for plasticizing and mixing Rubber Compound, Plastic ,Masterbatch ,Ceramic and Chemical materials

* Widely used for factory lab, universities and R&D institutions

Welcome to our Simptek Limited

Laboratory Dispersion Kneader Mixer Machine SPML-013

Laboratory Kneader Bambury | Internal Mixer | Rubber Processing Machine

Reviews

There are no reviews yet.