Description

Do you need a reliable rubber dispersion kneader ? It is for your industrial operations. Look to Simptek machinery . They are your trusted partner to get top-quality rubber machine equipment. Our rubber dispersion kneader ,also named as banbury mixer , are available in various capacity ,ranging from 35 litre to 150 litre,they are specially designed to meet your mixing and dispersion needs very well .

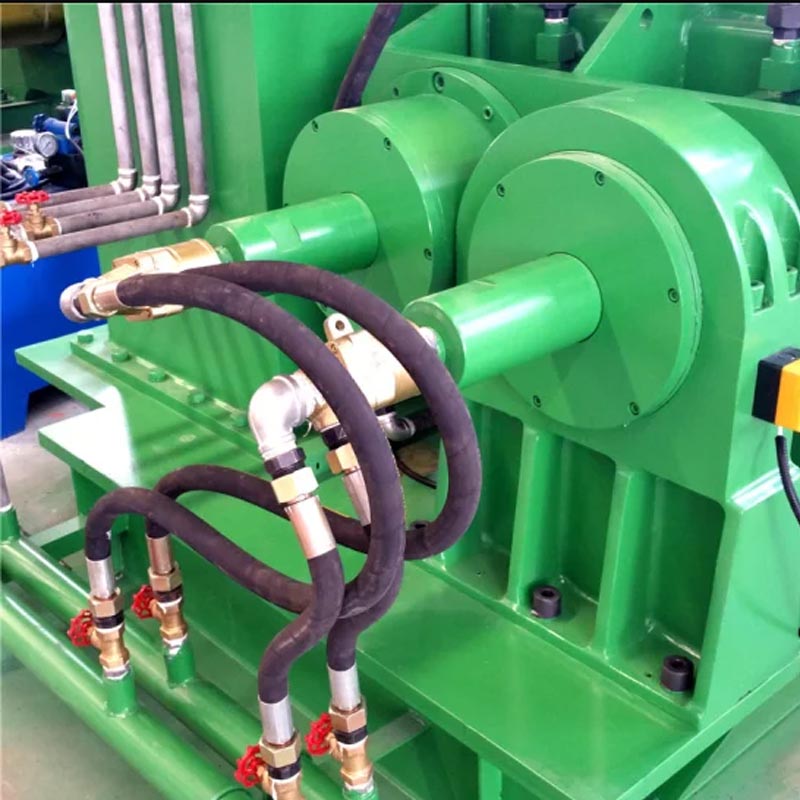

Our rubber dispersion kneader is designed with high precision, it is equipped with an automatic cooling system for maintaining stable , feature high speed mixing and excellent performance for complete efficiency of the rubber mixing process, they are applicable for various industries , from low viscosity adhesives to high viscosity rubber, this dispersion kneader is mainly used for plasticizing,masticating and mixing batch production , it is applicable for all kinds of rubber, plastic, color master batch, EVA ,TPR ,additives, chemical materials and other mixture etc.

The mixing movements in our dispersion kneaders are channeled by the specially designed contours of the rotor wings. Our banbury mixers provide effective mixing and dispersion for polymer compounds at an optimum horsepower input and operating temperature.

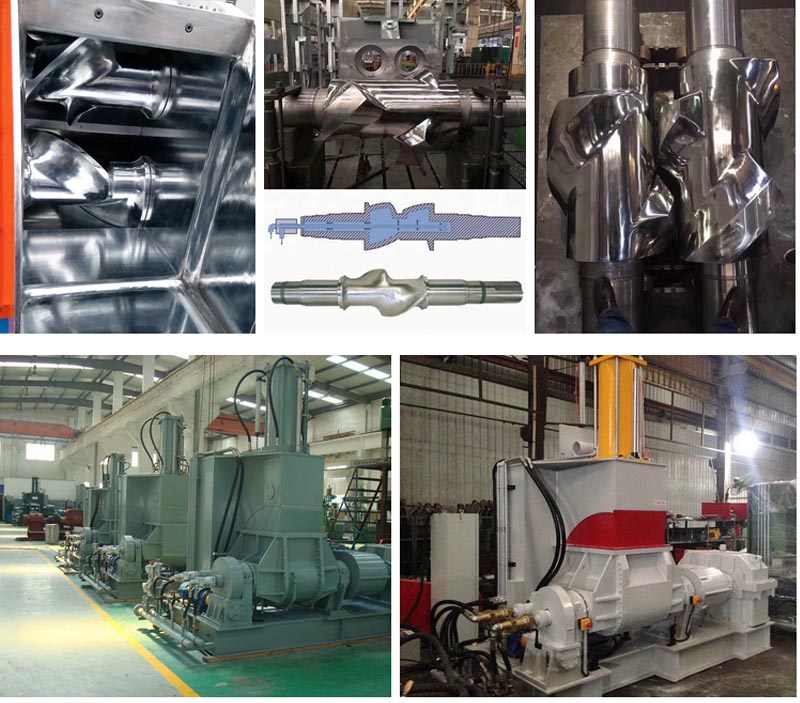

Material Construction Of Dispersion Kneader Banbury Mixer

* MIXING CHAMBER : Alloy Steel, Fabricated Hard faced, jacketted (both logitudinal & transverse) for steam heating & water cooling. Capable of Tilting to Approx, 140° for eay discharge & cleaning.

* MIXING ROTORS: Made of alloy cast-steel, spirally anullar design, with node tips i nternally cored for effective Tempretaure Control.The Land of the nodes are hard & profile ground.

* PRESSURE LID: Steel fabricated hard faced at mixing contact area, Jacketted for effective heating / cooling.

* DUST SEALS: Specially wet / dry type designed to keep environment Cleanliness & are easily replaceable.

* DUST EXHAUSTING DEVICE: Hovering Vapours / dust, absorbed by ducting to dust collector.Tilting to Approx, 130° for eay discharge & cleaning

Product Feature

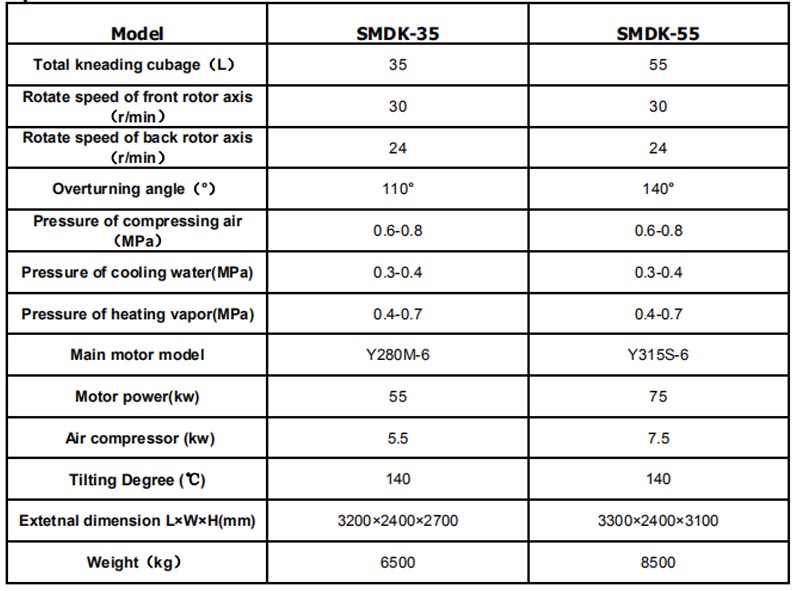

1. High performance : With a powerful 75 HP motor, this rubber dispersion kneaders machine ensures optimal performance ,deliverying consistent results every time.

2. Large Capacity : Its 55 litre capacity allows for substantial batches , which increase your productivity and streamlining production process.

3. Durable Construction: Built to withstand rigorous industrial environments ,our banbury mixing mixer machine is crafted from high-qaulity materials for long-lasting durability and reliability.

4. Versatile Application: The rubber dispersion kneader machine is suitable for mixing, kneading rubber and plastic compounds with different characteristics.

5. Use-Friendly : The kneader machine is designed for easy to operate and maintance. It is very simply to use , saving much of your time and effort.

Uses of Rubber DIspersion Kneader

Rubber dispersion kneaders are vital rubber processing equipment , they now become the most common ‘mixer’ in the rubber industry and highly demanded by many industries that process and make rubber,plastic ,silicone etc. The dispersion kneader are used for plasticizing , mixing ,kneading ,and dispersing rubber natural rubber, synthetic rubber, recycled rubber and plastics, foamed plastics etc. They ensure the final product uniformly , and create a rubber compound with desired properties. If you are making rubber products ,like sheets ,tires or belts, gaskets, sponge, soles, sandals, automobile, mechanical Goods etc,then a Dispersion Kneader Machine is key for getting the properties and satisfy you needs .

These Dispersion Kneader are energy efficient, maintenance-friendly, labor and time saving machinery that offers consistent quality of rubber mix compound at higher output as compared to an open mixing mill – thus making it truly Your Friend in ‘Knead’ for your rubber processing plant.

Why Choose Simptek ?

Simptek specialzies in custom making and supplying high-quality rubber processing machine in China. As one leading professional rubber machine manufacturer , our experienced staffs and professional engineers team ,enable us to provide fast and efficient serve to our valued customers . We also offer servicing and maintenance services ,manpower support and annual maintenance contracts .

Trust Simptek for all of your needs . They offer unmatched quality ,reliability ,and great serve . Contact us today to see our offerings . They will help your industrial operations reach new heights !

These automatical dispersion mixer machine are suitable for a wide range of material, ranging from low viscosity adhesives to high viscosity rubber. Our intensive banbury mixer are applicable for rubber,chemical, EVA, TPR, rubber soles, sandles, rubber rollers, tires, sponges, inner tubes, rubber rings, rubber tubes, rubber belts, wheels, erasers, packings, oil seals, fitness equipment, balls, bottle plugs, shock absorbing rubber, steam hoses, soft PVC flooring, adhesive tapes, rubber magnets, pigments, inks, corks, electrical parts, and other automobiles and motorcycles.

Stucutre Of Dispersion Kneader machine

Reviews

There are no reviews yet.