Description

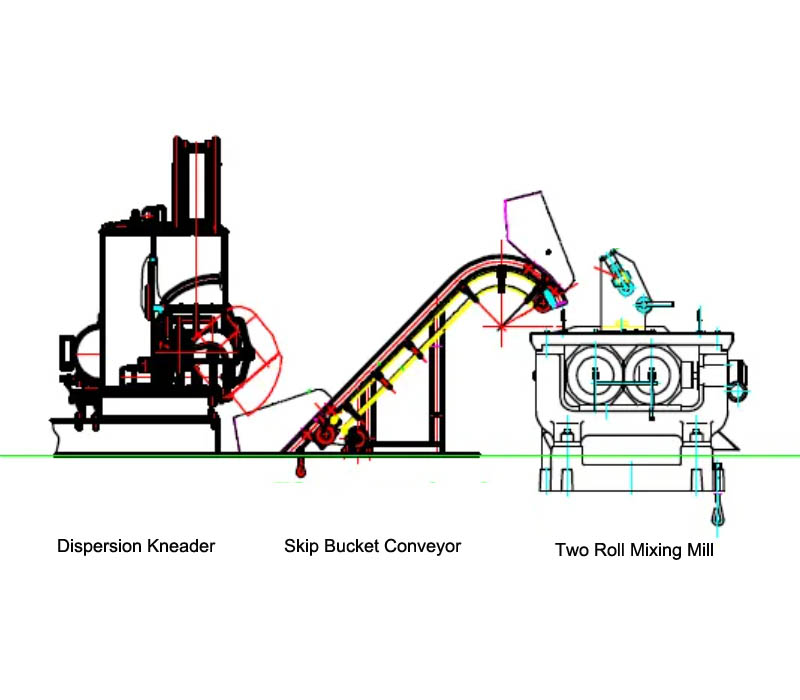

Rubber and plastic compounds are crucial in various industries from automotive to consumer goods . To achieve the desired material properties requires advanced processing machine ,that is banbury mixer ,also known as dispersion kneader.

The 35 litre Rubber internal mixers, also known as banbury intensive mixers, are advanced milling machines used to effectively mix and kneader rubber, plastics, and chemical materials for further processing. The dispersion kneader machine is necessary for the manufacturing of rubber strips before forming the outsole and foxing of shoes.

This rubber dispersion kneader machine is a specialized mixing machine designed to precisely blend rubber ,silicone and plastic compounds .This mixing machine ensures homogeneous compound dispersion, easy colour change cleaning, it work perfectly to control the mixing and blending of raw material and form a uniform compound mixture ensuring better dispersion. Its primary function include :

* Homogeneous Mixing :

The dispersion kneader has one counter-rotating rotors with specialized blades ,which ensure thorough and uniform mixing by continuously shearing and folding the plastic & chemcial compound material .This results in a compound with consistent properties ,satisfying the quality standards for various applications.

* Temperature Control :

The dispersion kneader machine features advanced temperature control systems, including heating and cooling capabilities, during the mixing process ,which is very crucial for achieving the desired material properties and preventing overheating.

* Reduced Processing Time :

Compared to traditional open mixing mill ,this dispersion kneader significantly reduce the efficient mixing time .

* Versatility :

This chemical dispersion kneader machine are applicable for a wide range of material ,including natural, rubber, syntetic rubber, plastic,chemical,EVA ,color masterbatch, TPR etc.

Simptek ,as one professional Rubber Processing Machine Manufacturer , we design and tailored a wide range of rubber machine, including 35 litre dispersion kneader mixer , 55 litre chemical dispersion kneader, 75 litres rubber dispersion kneader machine, 110 litres rubber dispersion kneader machine ,150 litres rubber dispersion kneader machine and 125 litres rubber dispersion kneader machine.

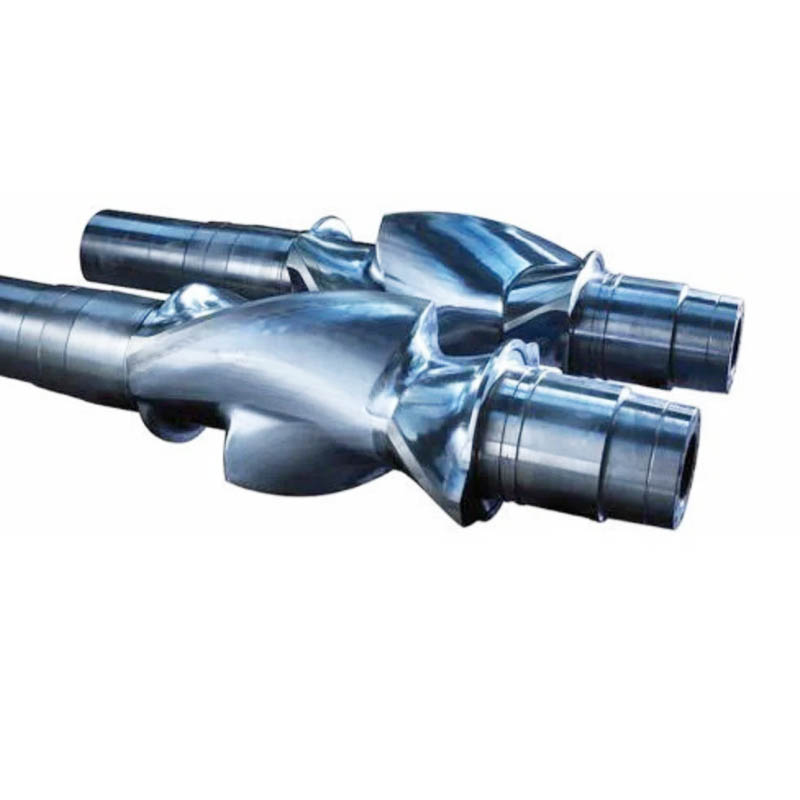

Material Construction Of Dispersion Kneader Machine

* MIXING CHAMBER : Alloy Steel, Fabricated Hard faced, jacketted (both logitudinal & transverse) for steam heating & water cooling. Capable of Tilting to Approx, 140° for eay discharge & cleaning.

* MIXING ROTORS: Made of alloy cast-steel, spirally anullar design, with node tips i nternally cored for effective Tempretaure Control.The Land of the nodes are hard & profile ground.

* PRESSURE LID: Steel fabricated hard faced at mixing contact area, Jacketted for effective heating / cooling.

* DUST SEALS: Specially wet / dry type designed to keep environment Cleanliness & are easily replaceable.

* DUST EXHAUSTING DEVICE: Hovering Vapours / dust, absorbed by ducting to dust collector.Tilting to Approx, 130° for eay discharge & cleaning

Product Feature

1. High Performance : With a powerful 75 HP motor, this rubber dispersion kneaders machine ensures optimal performance ,deliverying consistent results every time.

2. Large Capacity : Its 35 litre capacity allows for substantial batches , which increase your productivity and streamlining production process.

3. Durable Construction: Built to withstand rigorous industrial environments ,our banbury mixing mixer machine is crafted from high-qaulity materials for long-lasting durability and reliability.

4. Versatile Application: The rubber dispersion kneader machine is suitable for mixing, kneading rubber and plastic compounds with different characteristics.

5. Use-Friendly : The kneader machine is designed for easy to operate and maintance. It is very simply to use , saving much of your time and effort.

You Need Simptek Dispersion Kneader When

✓ You need much greater production.

✓ You need perfect Dispersion of Ingredients.

✓ You must avoid loss of expensive ingredients to atmosphere.

✓ Colours & ingredients change frequently.

✓ You need dust-free mixing.

✓ You want to use your space most profitably.

✓ You want to save on energy.

✓ Shortage of trained workers hits you frequently.

Application of Rubber Dispersion Kneader

* Automobile oil seals, body seals, Sponge,gaskets, belts, hoses compound and tubes

* Rubber for Electric wires

* Belt (Power transmission belt, Conveyor belt)

* Rubberized Rolls

* Silicon Rubber

* Rubber-based products such as plugs, caps, gloves, and dental supplies for the medical line

* Rubber product for Medical (Plug, Cap, Glove, Dental)

* Roll (Rubber, Plastic, Printing, Copying machine)

* Electric wires (Rubber, Plastic, Wire harness)

* E.V.A , Polythene, Thermoplastic Resins etc

* Bottle plugs, adhesive tape

* Chemical blending materials

* Sporting goods (Golf ball, Athletic ball)

* Food (Chewing gum)

Delivery for Free Tool

Reviews

There are no reviews yet.