Description

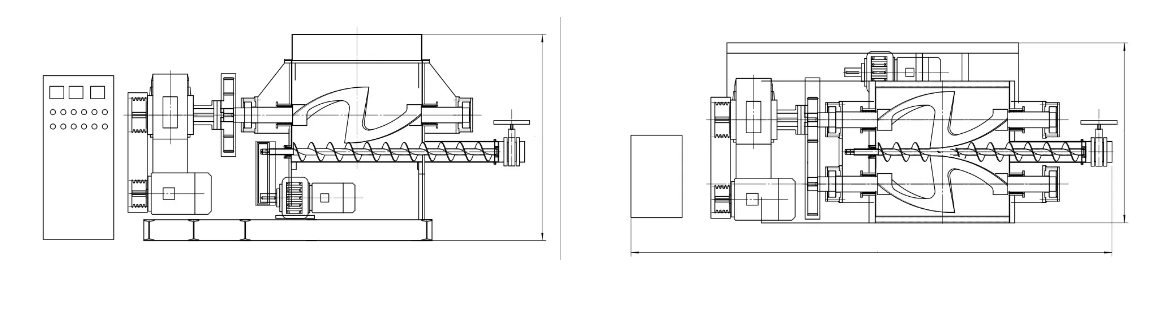

The sigma kneader is made of SUS304 stainless steel material ,it is a double arm mixer with extruder, the two “Z” blade rotate towards each others at same or different speed inside a W- shaped product container. Its inner extruder screw is located between the two blade with separate gear motor drive. The extruder screw rotate in forward direction for extruding process and rotate in reverse direction during mixing process. The speed of the extruder can be adjustable by VFD as per your specific needs . The twin screw basin kneading mixer machine with two horizontally arranged kneading blades, which are deeply geared into one another and strip themselves reciprocally. Each blade moves the material in opposite direction thereby providing excellent cross mixing of all raw materials. The blades pass the trough walls and each other at close clearances resulting in good mixing. The close clearance produces a shearing and tearing action that is beneficial to the size reduction of solids.

The extruder kneader mixer is designed to handle difficult to discharge products such as hot melts and butyl sealants, as well as other medium to high viscosity pastes. Such kneader mixer combines the action of the Double Arm Sigma Blade Mixer with an extrusion screw placed in the lower part of the mix trough. During mixing, the extrusion screw is run in reverse which imparts a third mixing action on the product, increasing mixing efficiency.

Such sigmal kneader mixer is specially used to knead or mix ,pulveriz high viscosity materials,it is suitable for many applications like mixing, kneading, Grinding, dispersion, drying etc, it is widely uses for mixing polyester putty,silicone rubber, rubber solution, biscuit dough, sauce,cellulose and battery,ink,pigment,Paint, Polymers Plastic, Putties,dyestuff, polymers etc.

The kneader mixer machine provided by us is manufactured at our well-developed production unit, equipped with ultra-modern technology using high quality components. Beside this, our valuable clients can avail this Industrial twin arm sigma mixer from our manufacturer in a variety of technical specifications at very affordable price.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Working Principle of Sigma Mixer

The working principle of sigmal mixer machine is same with the rubber mixing machine ,it is highly popular mixing equipment used for efficiently mixing and kneading high viscosity materials with utmost ease by ‘Z’ type (SIGMA) shaped kneading blades.

In the sealed mixing chamber, under the pressure of upper ram, the two blade rotates very accurately at different speed towards each other. These high-viscosity materials would be plasticized or mixed into the new required material by shearing, squeezing, stirring, rolling and other kneading.

Design of Sigma Mixer

The Sigma Mixers can be tailored manfaucture and supplied in a variety of design and capacity ,ranging from 200Litre to 3000 litre according to your different application requirements. Here are some mail features are below:

*Blade Material: Material option of AISI 1030, AISI CF8 & AISI CF8M

*U Trough: Construction gauge offered from 5 mm thick up to 35mm thick in iron or stainless steel can be 201 ,304 or 316 options.

*Motor horsepower: Motor horsepower ranging from 1.5 H.P. up to 250 H.P power.

*Power Voltage: 308V,440V ,or any other standard voltage requirements.

*Rotation speed: Fix and variable speed RPM offered with option of variable frequency drive.

*Feeding: Feeded by manual or vacuum/screw type automatic feeding can be offered.

*Discharge: Manual, chain type and hydraulic type automatic tilting , or screw type side discharge system

*Heating: Steam heating, electrical heating available

*Cooling: Jacket offered for cool water circulation

Standard Design(Customizable)

* Material: SUS 304, 316 or mild steel

* Discharging: Tilting discharging/Screw extruding discharging/Bottom plate

* Heating: Electric heating/Water heating/Oil heating/Steam heating

* Cooling: Water cooling/Jacket cooling

* Vacuum: Water-ring vacuum pump/ buffer tank.

* Motor: Explosion proof motor

* Independent Control Panel: Variable speed/ Temperature/Discharging

* Working Volume: 5 to10,000 Cubic Feet (from experiment to production)

Technical Specification of Sigma Mixer

| Type | SMP-5 | SMP-10 | SMP-100 | SMP-300 | SMP-500 | SMP-1000 | SMP-1500 | SMP-2000 | SMP-3000 | SMP-4000 | SMP-5000 | |

| Total Volume (L) | 5 | 10 | 100 | 300 | 500 | 1000 | 1500 | 2000 | 3000 | 4000 | 5000 | |

| Mixed amount/batch (L) | 1.5-3.5 | 3.0-7 | 30-70 | 90-210 | 150-350 | 300-700 | 450-1050 | 600-1400 | 900-2100 | 1200-2800 | 1500-3500 | |

| Rotation Speed (rpm) | 42/34 | 42/34 | 37/21 | 37/22 | 37/23 | 37/26 | 37/22 | 30/21 | 30/21 | 30/20 | 28/18 | |

| Main Motor Power (Kw) | 0.75-1.5 | 1.1-3 | 5.5-11 | 7.5-30 | 15-37 | 22-90 | 22-90 | 30-110 | 30-110 | 45-110 | 55-132 | |

| Heating Methods | Steam Pressure (MPa) | Jacket for steam | ||||||||||

| ≤0.3MPa | ||||||||||||

| Electric Power (Kw) | 2.4 | 2.4 | 6 | 12 | 18 | 30 | 45 | 54 | 72 | 72 | 90 | |

| Vacuum (MPa) | 0~ -0.096Mpa (Vacuum Kneader) | |||||||||||

| Discharging Method | Tilting cylinder | |||||||||||

| Screw extrusion | ||||||||||||

Operation of Sigma Blade Mixer

Firstly, the material to be mixed is fed through the top of the kneader mixer’s container , about 40 to 65 percent of the mixer’s total volumetric capacity. The inner blades are rotating through heavy duty drive systems,which mainly consist of a motor, gearbox, couplings, and gears. The speed of rotating blade can reach up to 60 metres per minute. Basically , the mixing homogeneity upto 99% within 10 to 30 minutes.

The mixer troughs can be provided with jackets for circulation of hot or cold media to maintain the required temperature conditions within the k eader mixer machine. The discharge of the material from the kneader mixer container is either by tilting of the mixer container, bottom discharge valve or through an extruder / screw located in the lower portion between the two trough compartments. The tilting arrangement of the container may be designed for manual operation or may be mechanized using motorized or hydraulic arrangement.

Application of Sigmal Mixer

The sigma mixer is widely used for mixing and kneading of low-to-high viscosity products in many industries such as ceramics, silicone rubber, sealants, clay, pasty, sticky, and gritty slurries with high viscosities ,they are also very ideal for many other industries as follows:

Chewing gum

Adhesives

Biscuit dough

Butyl rubber

Carbon pastes

Ceramics

Chemicals

Rubber

Plastic

Polymer

Chewing gum

Cosmetics

Crayon and pencil lead

Bakery food

Pharmaceuticals

Inks

Pigments

Chocolate and other food products

Reviews

There are no reviews yet.