Description

ooking for a machine that is reliable, efficient, and easy to operate? Look no further than the Two-roller rubber calender machine.

Calender machines are one of our specialties. These robust machines combine extremely high compression capability with precision.

This calendaring machine is specifically designed to roll out rubber sheets, making it an excellent choice for those who need to manufacture sheets for various applications. The rolls are made of chilled alloy cast iron, which ensures that they maintain their shape and durability even under extreme conditions. Additionally, the machine is equipped with various features that make it easy to use and navigate.

Calendering machine is a continuous process which adopt heated rollers that are fed with a pre-compounded paste-like mass. The rollers of calenders machine are made up of chilled cast iron with vanadium and titanium alloys, which are hard and anti-wear. These rolls are separately driven by DC motors, which allow you to adjust the speed range separately.

This two-roller rubber calender machine can efficiently used for calendering of rubber or plastics, fabric fraction and coating, and sheeting. These calender machine are mainly used to press the mixed and refinded rubber mixture or many kinds of plastic ,rubber mixture into uniform-thickness of films, sheets, and plates. Beside , it also can be widely applied to rubber or plastic sheets in single or double sticking operation with textile fabrics

The calendering machine includes two rollers, a motor, reducer, friction gear, distance regulator, thin oil lubrication device, and other main parts/components.

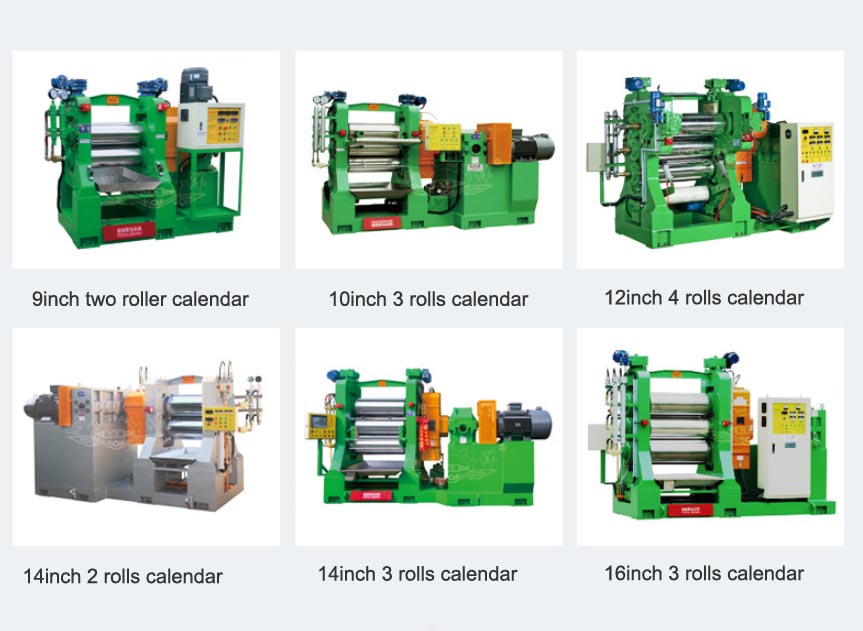

Our calendar machine have different configuration, it is available in two, three, four and five rolls .

Uniform End Result

An exclusive method of heating special cylinders allows for close and constant temperature control, which therefore guarantee excellent bonding/lamination and print quality in terms of uniformity .

Wide Range Of Operating Temperatures

The wide range of temperatures that can be achieved with our custom-built cylinders (ambient temperature up to 225 °C) means that substrates with different properties and requirements can be processed easily.

Management Of Substrates During Heat Transfer Printing Process

With our extensive experience, we can advise on the best devices for managing and handling materials to be treated (woven fabrics, mono and bi-stretch fabrics, etc.)

Machine Configuration

* Different working speeds are possible with heated cylinders from 215 up to 1000 mm in diameter

* Cylinder widths from 1600 up to 3600 mm

* Selection of machines ranging from particularly compact versions to configurations for high-volume production

* Wide range of options available, depending on the chosen application and substrat

* Bonding Machine can be also used as Sublimation Calender processing and heat setting.

Feature

* High reliability: the calender machine is made of sturdy manufacturing materials with good abrasion and corrosion resistance and long service life.

* Uniform Calendering: The two rolls calender machine consists of two rollers, which can better process the raw materials evenly and improve the production quality.

* Precise Control: the calendering machine has adjustable roller distance and pressure control system, by adjusting the processing parameters, it can meet various working needs.

Precise Temperature Control: Ensures uniform heating by adjusting roll er’s temperature, preventing fabric damage, and maintaining quality specifically for different materials and thicknesses.

* Efficient Automated Control: Automatic operations, reduces errors, and monitors performance with intelligent systems, greatly improving safety and stability.

*Multi-Functional: the calendering machine is suitable for a wide range of materials, such as rubber, plastic, PVC, silicone, textile ,cloth etc.

* Energy-Saving and Eco-Friendly: Optimizes energy use, reduces consumption, and adheres to environmental standards with low-noise, eco-friendly materials.

*Reducing scrap: The two -roller calender can greatly reduce the production of scrap and defective products due to uniform calendering and high control precision.

*Easy to operate: Very easy and convenient to operate the multi-roll calender , it doesn’t need complex training before usage .

Specification

| Model | SMPCM-6 | SMPCM-8 | SMPCM-10 | SMPCM-12 | SMPCM-14 | SMPCM-16 | SMPCM-18 | SMPCM-22 | |

| Roll Diameter | Inches | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 22 |

| mm | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 550 | |

| Face Width | Inches | 18 | 24 | 30 | 36 | 42 | 48 | 54 | 66 |

| mm | 455 | 610 | 760 | 915 | 1065 | 1220 | 1370 | 1675 | |

| Motor | H.P | 7.5 | 10 | 15 | 30 | 40 | 60 | 100 | 150 |

| R.P.M | 980 | 980 | 980 | 980 | 980 | 980 | 980 | 980 | |

Multi Rolls Calendar Machine

Simptek Calender Machine Advantage

Customizability: The two-roller calender machine can be customize and tailored in different configuration as per your specific work requirements.

Controllability: By adjusting the pressure and clearance of the rollers, the thickness and texture of the rubber can be precisely controlled.

Efficiency: The calender can produce a large amount of material continuously, which greatly improves the production efficiency.

Versatility: The machine has a wide range of applications in material processing and is suitable for many types of materials, such as rubber, plastic, silicone, food and so on. This versatility makes it suitable for almost all production needs.

Environmentally Protection : the two Rolls Calender Machine can be equipped with a recycling system to minimize energy waste and reduce the impact on the environment.

Stability: the calendering machines are usually very robust, capable of continuous operation, stable performance and long service life, but requiring less maintenance.

Wide Application

*Rubber & Elastomers Related Products :Applied to rubber and rubber related products,such as tires , conveyor belts , gaskets , rubber tubes, seals, rubber pads etc.

*Silicone Products : Silicone is often used in electronics, medical, food and other industries due to its good high temperature resistance and aging resistance.

*Textiles and Fabrics: In the textile industry, the calendering process can enhance the luster, smoothness, and drape of textile and fabrics, it can increase their dimensional stability and abrasion resistance,it is widely applicable for Bicycle/Auto/Tires/Motorcycles, Single coating/double coating etc. The calendering machine is also suitable for paper, film, nonwoven etc.

*Composite Materials : Used to produce the middle layer of composite materials, such as carbon fiber reinforced plastics (CFRP), etc., and calendering is used to ensure that the layers of materials are tightly combined.

*Plastics and Polymers: The calendering machine are also suitable for production of various plastic and polymer-based products, ideal for polyvinyl chloride (PVC), polyethylene, polypropylene, and other thermoplastic resins ,so that achieve desired surface finishes, thicknesses, and physical properties.

*Floor Tiles: The rolls calendering machine are widely used to manufacture rubber floor tiles, which are widely adapted for playgrounds, gymnasiums, or high-traffic areas. You can cut them to meet custom flooring needs.

*Rainwear:The commingled fabric and rubber polymer result in the formation of raincoats or jackets.

*Luminous Ceilings:The calendering machine are also widely used to form very thin rubber sheeting that you can use in your ceilings.

*Furniture Upholstery: Rubber webbing replaces jute webbing because of unmatchable strength, flexibility, and durability. You can use it on various furniture accessories to make them aesthetically pleasing.

Reviews

There are no reviews yet.