Description

In the manufacturing in many industries, particularly in rubber, textiles, PVC , cloths and plastics industries, the multi rolls calender machine stands out for its versatility, precision, and efficiency.

A calendere machine is a series of hard pressurized rollers used to finish or smoothen a sheet of paper and they are heated or cooled as required, it is used to press, flat, and polished material ,such as textile,cloth ,paper,PVC, fabric,rubber,vinyl ,polymer etc. Through this continuous compresses and smooths process for these material, it finally produce uniform standalone material sheets with custom width and thickness, which can be adjustable for the rolls as per your specific requirement.

This versatile 2-rolls rubber calendering machine is widely applicable in various industries. It is particularly popular in the rubber industry for producing sheets of rubber, which are then used in various applications, including tires, gaskets, and conveyor belts. In the plastics industry, this multi rolls calendering machine is used to manufacture films and sheets that are essential in packaging, automotive parts, and construction materials.

And if this multi rolls textile calendering machine is used in the textile industry , it would impart different finishes on textiles, such as a glossy or matte surface as per your specific needs . This versatility makes such multi purpose 4-roller fabric calender machine a valuable asset for manufacturers looking to expand their product offerings or improve the quality of their existing products.

Product Advange

1. Versatility : This versatile textile calendering machine is capable of handling a wide range of material , including rubber ,textile,PVC ,EVA foam, polymer ,paper etc

2. High Precision Calendering : This double roller configuration ensures superior precision in the calendering process . It can help to achieve the desired thickness ,smoothness, and surface finish for your materials .

3. Wide Range of Sizes: The custom calendering machine can calender material’s width ranging from 100mm to 21000mm . It can accommodate varying material widths ,offering flexibility for different production requirements.

4. Advanced Control Systems : This calender machine can be equipped with PLC control ,which allow operator can set and adjust parameters for optimal performance , siginificantly ensures efficiency ,repeatability and ease of operation.

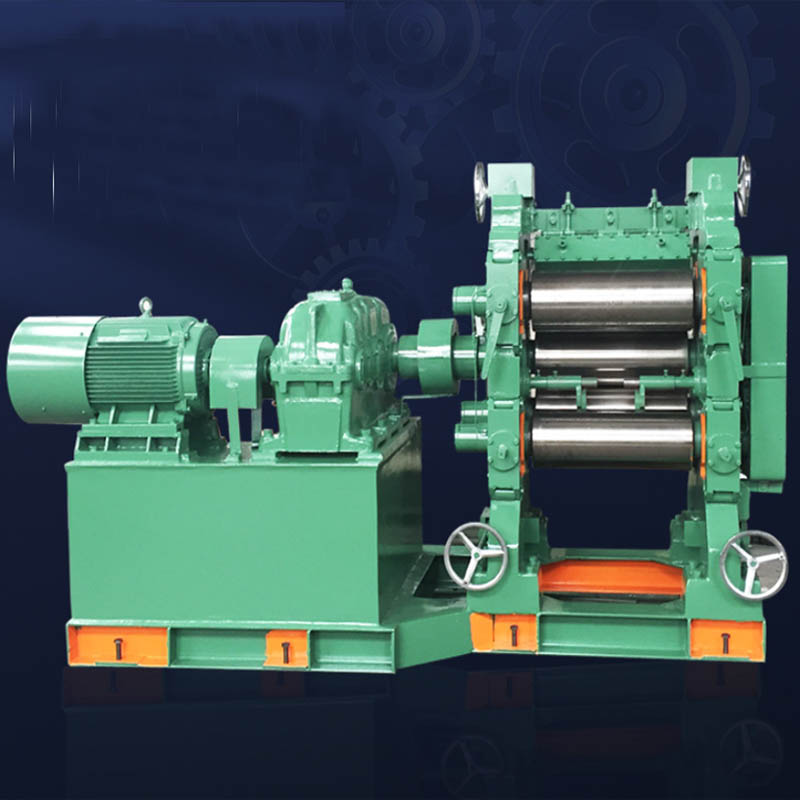

5. Robust Construction : This robust 2-rolls calender machine feature robust frame and high quality componets ,which guarantees a long lifespan and minimal maintenance requirements .

6. Efficient Heating System : Our calender machine incorporates an efficient heating system to maintain the required temperature throughout the calendering process ,which ensures consistent and high quality calendering results .

Feature & Function

* Precision Calendering : The 4 rolls designed calender machine ensures precise and uniform calendering, producing a smooth and polished finish on your textile material. This calendering machine is equipped to handle a wide range of fabric ,rubber ,paper ,cloth ,PVC etc.

* PLC Control System : Control your production process with the integrated PLC control system . This advanced technology allows for easy operation and precise adjustments ,which ensure consistency of product quality. Its use-friendly interface allows operators to set parameters ,monitor progress and make real-time adjustment according to your needs .

* Wide Application : No matter your material is cotton ,textile ,polyester or other rubber material ,this versatile multi rolls calendering machine are your best choice for textile manufacturing.

* Robust Construction : Built by high quality ,this calendar machine boasts a robust and durable construction,which ensure its longevity and minimal maintenance requirements.

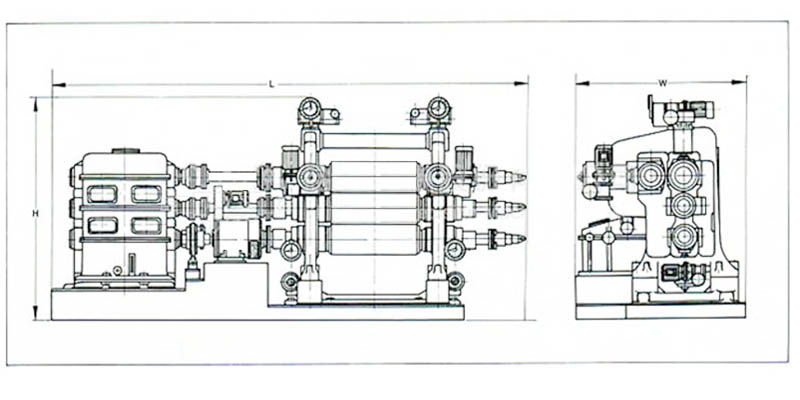

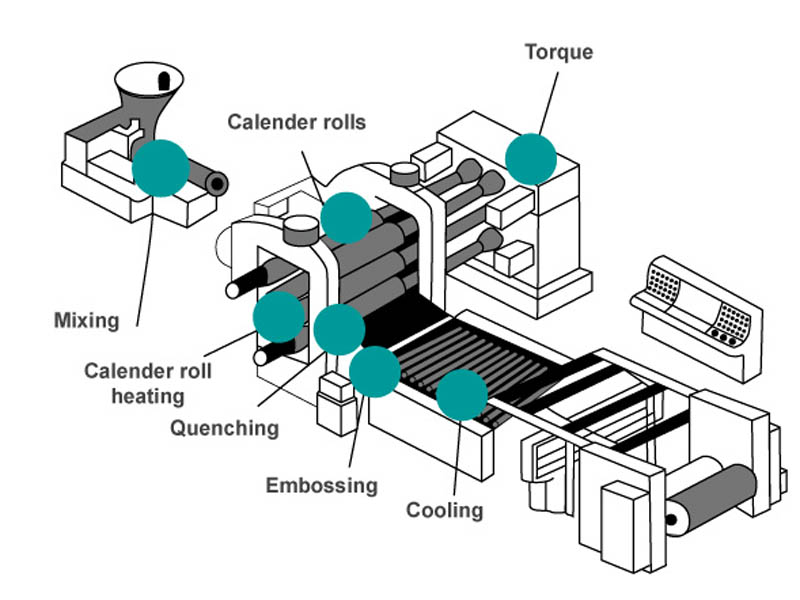

Structure of Calendere Machine

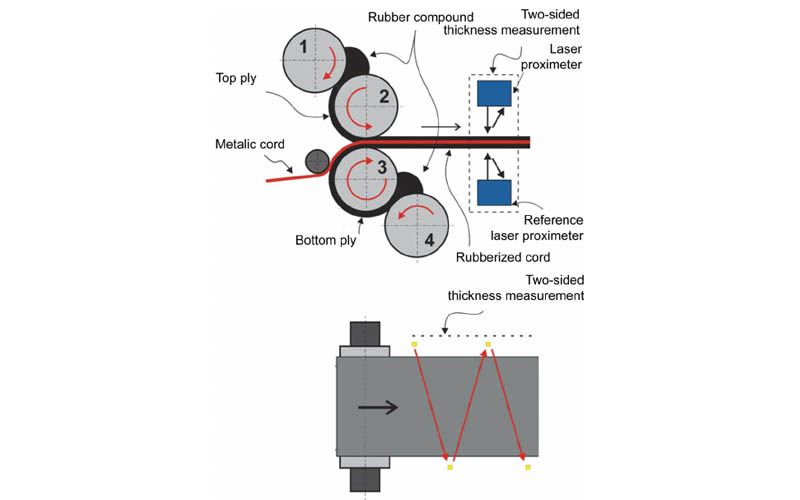

How does a Calendering Process Work?

The calendering process is a finishing operation widely used in many industries , like rubber , paper, textiles, cloth , plastic ,PVC, EVA film etc . A calender machine adopt a series of hard pressure rollers by passing them under significant pressure , in order to form or smooth a sheet of material

Here is how the calendering process works:

Step 1. Material

Firstly ,the compound material to be process, such as rubber ,fabric, textile ,paper, nonwoven, composite ,PVC or plastic EVA film, is prepared and fed into the rolls calendering machine. Of course ,before the process of calendering , these material may need pre-treatment processes such as drying, softening.

Step 2. Roller Configuration

The calendering machine consists of two or more chilled steel rollers, whose hardness can reach up to 70 HRC. These rolls may be arranged in several configuration, either vertically or horizontally in L style ,I style or Z format.

Step 3. Passing Through Calender Rolls

The material to be calendered, go through these pressurized rollers , which can be heated or cooled, depending on the material and your desired outcome. When the material passes through the nip among the rolls ,which create high pressure compresses on the material, reducing its thickness and increasing its density.

Step 4. Controlling the Rolls

Its speed, temperature, and gap between the rollers can be adjustable to control the degree of calendering. Through these series of operation , it can precisely control for the properties of thickness ,smoothness ,gloss of final material.

Step 5. Cooling and Winding

After the material are passed through the rollers, the calendered material need to be cooled or cut into desirable sheets according to your specific needs .

We Offers Various Roller Calender Machine

I Type vertical

L Type

Z Type

Two Rolls Calender

Three Rolls Calender

Four Rolls Calender

Five Rolls Calender

I-Type

This style exsit in 2 roller ,3 rolls and 4 rolls calendering machine . Its upper and lower roller rotates anticlockwise among these series of hard pressure chilled rollers , so that obtain the desired thickness, width and surface or smooth a sheet of material such as paper, textiles, rubber, or plastics

L-Type

L style textile calender machine ,just as its name ,with its L-shaped roll arrangement and adjustable line forces in the top nip and rear nip ,which provide not only this specific soft handle effect, but also a multitude of other effects, including smoothness and density.

Z-Type

With the name of Z-style arrangement. In this type, each roller is perpendicular to another pair roller. You can face a lower level of heat in this type compared to the other two roller arrangements above.

Wide Application

*Rubber & Elastomers Related Products :Applied to rubber and rubber related products,such as tires , conveyor belts , gaskets , rubber tubes, seals, rubber pads etc.

*Silicone Products : Silicone is often used in electronics, medical, food and other industries due to its good high temperature resistance and aging resistance.

*Textiles and Fabrics: In the textile industry, the calendering process can enhance the luster, smoothness, and drape of textile and fabrics, it can increase their dimensional stability and abrasion resistance,it is widely applicable for Bicycle/Auto/Tires/Motorcycles, Single coating/double coating etc. The calendering machine is also suitable for paper, film, nonwoven etc.

*Composite Materials : Used to produce the middle layer of composite materials, such as carbon fiber reinforced plastics (CFRP), etc., and calendering is used to ensure that the layers of materials are tightly combined.

*Plastics and Polymers: The calendering machine are also suitable for production of various plastic and polymer-based products, ideal for polyvinyl chloride (PVC), polyethylene, polypropylene, and other thermoplastic resins ,so that achieve desired surface finishes, thicknesses, and physical properties.

*Floor Tiles: The rolls calendering machine are widely used to manufacture rubber floor tiles, which are widely adapted for playgrounds, gymnasiums, or high-traffic areas. You can cut them to meet custom flooring needs.

*Rainwear:The commingled fabric and rubber polymer result in the formation of raincoats or jackets.

*Luminous Ceilings:The calendering machine are also widely used to form very thin rubber sheeting that you can use in your ceilings.

*Furniture Upholstery: Rubber webbing replaces jute webbing because of unmatchable strength, flexibility, and durability. You can use it on various furniture accessories to make them aesthetically pleasing.

* Frictioning of fabrics for bicycle/motor cycle/auto tyres

* Nonwoven Fabrics in Disposable Diapers Nonwoven Fabrics in Car Seats Magnetic Tape

Simptek Calender Machine Advantage

Customizability: The two-roller calender machine can be customize and tailored in different configuration as per your specific work requirements.

Controllability: By adjusting the pressure and clearance of the rollers, the thickness and texture of the rubber can be precisely controlled.

Efficiency: The calender can produce a large amount of material continuously, which greatly improves the production efficiency.

Versatility: The machine has a wide range of applications in material processing and is suitable for many types of materials, such as rubber, plastic, silicone, food and so on. This versatility makes it suitable for almost all production needs.

Environmentally Protection : the two Rolls Calender Machine can be equipped with a recycling system to minimize energy waste and reduce the impact on the environment.

Stability: the calendering machines are usually very robust, capable of continuous operation, stable performance and long service life, but requiring less maintenance

Reviews

There are no reviews yet.