Description

High precision lab vulcanizing machine is also known as laboratory hydraulic press equipment, it is mainly applicable for R &D in the laboratory.

This lab vulcanizing machine consists of a host, hydraulic systems, electrical control system, it is equipped with a high-performance hydraulic system, which features with automatic pressure compensation function.

The rubber vulcanizer press machine has two working layers, its upper one is for the heating plate, which is heated by electricity and its lower one is a cooling plate, which is cooled by a tap water cooling system.

When produced, the raw rubber material is placed in the casting mold and clamped between the electric-heating flat plates, so that to apply pressure and temperature. By heating, this hydraulic press equipment would make the material shaping, testing, and serving as the basis for the ingredient of mass production.

We custom-made and supply a variety of hydraulic press equipment, they are available from 10ton to 300 ton, they are available in automatic control or manual control.

Key Componets

*Heating System: Provides the necessary heat for the vulcanization process

*Pressure System: Applies pressure to the rubber compound during curing

*Mold: Shapes the rubber material into the desired final products

*Control System: Regulates the heating and pressure cycles

How Do Vulcanizing Press Work?

1. Pre-treament Of Material :the rubber material to be vulcanized needs to be pre-treated, for example the material should undergo these process ,such as rubber cutting, crushing & blending, and mixing & kneading.

2. Charging and Loading Mold :the material treadted are sent to the rubber vulcanizer equipment for curing .The material are usually mixed with additives such as vulcanizing agents, accelerators, preservatives, and fillers to form a uniform rubber mixture.

3. Setting Heating & Pressure :Set some certain temperature and pressure ,process time for the vulcanization machine,which are controlled by PLC system .

Basically ,the vulcanization temperature can be adjustable as per different rubber materials and vulcanization requirements ()between usually between 140°–180° ). The vulcanization time is usually longer and can last from a few minutes to several hours.

4. Cooling and Curing: When the vulcanization reaction is completed, the hydraulic vulcanizing press machine starts the cooling system to cool the vulcanized rubber products, to cure their shape and structure.

What Does a Vulcanizer Do?

A vulcanizing press machine is a equipment used for processing rubber, which can vulcanize rubber to improve its elasticity, wear resistance, and aging resistance. The rubber vulcanizer press machine is widely applicable for the rubber ,silicone and plastic machinery industries. It has the functions of automatic temperature control, automatic timing, and alarm .

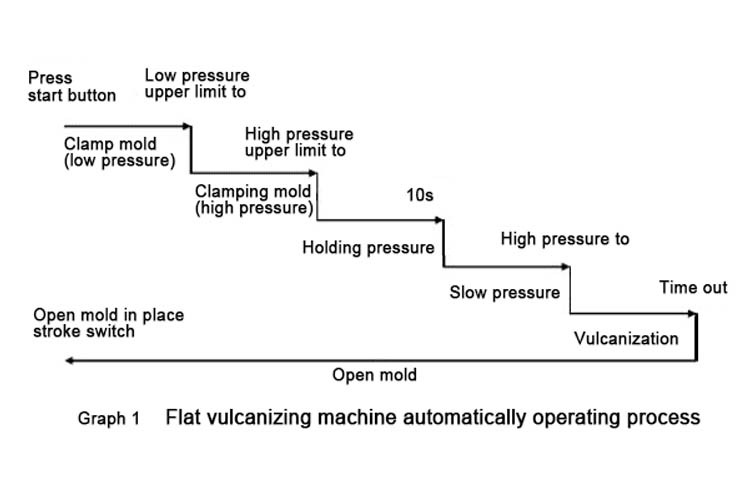

The automatic laboratory vulcanizer is controlled by PLC with computer automatic detection system, it feature user-friendly programming design, can automatically complete mold, forced mold opening, mold transfer.

Application

The vulcanized rubber material feature higher tensile strength and thermal stability and durability ,it is 10 times more stronger than natural rubber. The vulcanized rubber material can be widely used to produce many products ,including

Shoe soles

Hockey pucks

Bowling balls

Motor mounts

Suction cups

Rubber Seals

Rubber gasket

Rubber O-rings

Conveyor Belts

Foam Plastic

Thermosetting Plastic

Cell Phone

Keyboard

Sealing Seal

Medical Silicone Products

Sports Equipment

Toys

Erasers

Hockey Pucks

Shock absorbers

Rubber Floor Tiles

Rubber Gound Mats

Rubber pads

Thermosetting plastics

Foam

Resin

Building materials

Jhon Attack –

We’re a financial and consulting business company of professional thinkers, strategists, digital innovators, designers and problem solvers (everyone gets a mention). Our sense of curiosity brings thinkers, strategists, digital innovators, designers and problem solvers (everyone gets a mention).