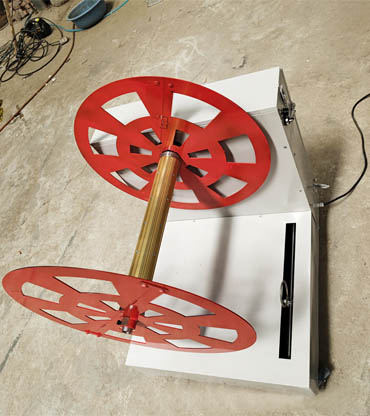

* Made of high-strength and low-stress steel wallboard

* Designed to wind and collect the edge trim during bag making processes.

* Especially suitable for rewinding high tensile strength material.

* Low power consumption due to efficient use of power

* Driven by a torque motor, providing synchronous motion with the main machine

* Traversing of trim is fully mechanically controlled

* Winding Profile type is Pineapple

* Trim Width : 5mm To 50MM

* Maximum Speed : 0 to 500 MPM (*Speed depends on type web, thickness, material quality etc.)

* Dancer : Ultrasonic Sensor Mechanism

* Cantilevered Winding Shaft allows fast change

* Variable traversing facilitates flexibility to wind winder and narrow trim efficiently

* Low power consumption due to efficient use of power

* Simple wind tension adjustments

* Max. Winding Diameter 350mm

* Max. Winding Width 500mm

* Voltage: 380V/415V or custom

* Power(W): 400W

Welcome to our Simptek Limited

Edge Trim Film Rewinder SPW-004

Edge Trim Rewinder | Cable Coiling Machine | Slitting Winder Machine

Reviews

There are no reviews yet.