This Twin screw extrusion granulator machine is suitable for the mixing, plasticizing and extrusion processing of recycling and pelletizing PP, PE, PET, PS, PA, PA6 ,engineering plastics, modified plastics, waste plastics and color masterbatch with variable colors etc., with plasticizing homogenization, color proofing, filling modification and other functions. It can be used in laboratory tests, quality control, teaching research and small-scale production.

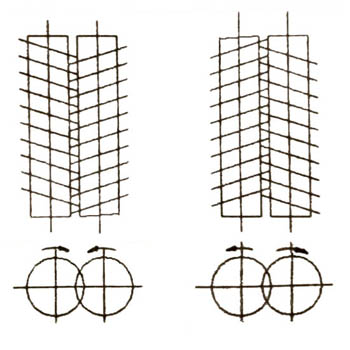

This double screw extruder machine mainly consist of feeding system, extruding system, cutting system, heating system, driving system, cooling system and two parallel screw which is the key conponents and can be co-rotating rotate clockwise or counter-rotating counterclockwise. For the co -rotating extrusion machine, one screw wipes the other screw but doesn’t create high shear against the walls of the barrel. They are specially used for mixing, devolatilization and reactive extrusion.

While for counter-rotating extruding machine ,its two screws rotate in opposite directions. One screw rotate clockwise while the other one rotates counterclockwise. This conter-rotating configuration generates an intensive contact zone between these two screws, which promote greater plasticization of the raw material. Basically , counter-rotating extrusion machine are widely used when more interaction is needed between the polymer components or when highly viscous materials are being processed.

When the raw material is fed into the barrel through its hopper and it is transported through the screws towards the end of the barrel. The screws are designed used to compress and heat the raw material to a specific temperature range as per your needs, which would converte the material into a homogeneous mixture. This compound mixture is then forced through a die and cooled to form the desired product. The design of twin screw provides a high degree of mixing and kneading action, which enhances the plasticization and homogenization of the raw material.

We are a leading Manufacturer of twin screw extruder, twin screw extruder machine, high capacity pvc granule extruder machine, biodegradable granule making machine, twin extruder machine and twin extruder, we has been designing and manufacturing high-quality bespoke plastic extruders according to your specific needs .

Reviews

There are no reviews yet.