Description

Ribbon blender mixer is a horizontal mixing machine that is well suited for the efficient blending of free-flowing materials , it is mainly used for effective mixing of a variety of substances that vary from dry powders,viscous pastes, creams industries etc .

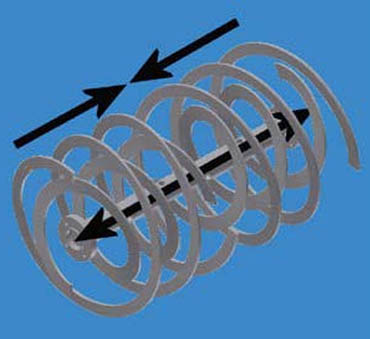

The stainless steel Ribbon Blender mixer is a high speed, high capacity batch mixer equipment for the homogeneous blending of dry, free-flowing solids.This Ribbon blender machine usually consist of a U-shaped horizontal trough in one-piece weldment with one or multiple helical agitators or “ribbons” that blend, fold, and agitate material using both an axial and radial motion in opposing directions. Its agitator is made up of inner and outer helical ribbons

The ‘U’ shaped trough is made of quality stainless steel material ,which ensures reliability and longevity, it allows for easy access and shorter cleaning times between each batch.

Full homogenisation of the products is achieved thanks to the efficient blending action of the spiral or ribbon blades .

Simptek ribbon blender mixer features for hygienic mixing, easy maintenance, avoidance of cross contamination and high mix quality are all standard paramount in the U-Trough mixer design.

Ribbon Blender Technical Specification and Capacity

| MODEL | SMPRM150 | SMPRM500 | SMPRM1000 | SMPRM2000 | SMPRM3000 | SMPRM4000 | SMPRM5000 | SMPRM7500 |

| GROSS CAP. (LTRS) | 150 | 500 | 1000 | 2000 | 3000 | 4000 | 5000 | 7500 |

| WORKING CAP. (LTRS) | 100 | 325 | 650 | 1300 | 2000 | 2600 | 3250 | 5000 |

| DIMENSION IN MM (L*W*H) | 1600*800*1250 | 1800*800*1300 | 2500*1000*1500 | 3500*1200*1750 | 4000*1500*2000 | 4500*1800*2000 | 4950*1800*2000 | 5450*2000*2000 |

| RPM | 15/30 | 15/30 | 15/30 | 15/30 | 15/30 | 15/30 | 15/30 | 15/30 |

| HP | 3/5 | 5/5 | 7.5/10 | 10/15 | 20/25 | 25/30 | 30/40 | 40/50 |

Benefits of Choosing a Simptek Ribbon Blender Mixer

Simptek Ribbon Blender mixers are ideal for certain kinds of trail mixes with friable and delicate ingredients, food products containing discrete vegetable or fruit pieces, polymer beads, sands and ceramics, to name a few. The stainless steel paddle blender mixer can heat, cool, or dry materials under vacuum. It can also coat solid particles with small amounts of liquid. In addition, it can mix wet applications such as soups, batters, slurries and certain pastes.

How Does a Ribbon Blender Mixer Work?

The horizontal ribbon blender workds with an inner ribbon that carries the material from the center to the outside and an outer ribbon that moves the material from two sides to the center. When moving the materials , the two ribbons are joined a rotating direction. The horizontal ribbon blender allow you to mix in less time while getting a better result

Mixing Process:The mixing process begins when the materials are loaded into the mixer container. Once the container is loaded, the motor is turned on and the paddles begin to rotate.The shaft is driven by a motor that is actually connect with paddles ,which are precisely pitched to move material both radially and axially in opposite directions.

Mixing Time: The amount of mixing time rely on the type and volume of materials being mixed. However, most paddle mixers have a set mixing time that can be adjusted depending on the application.

Application of Paddle Blender Mixer

The industrial paddle mixer can mix any powder with granular ,powder with powder ,and it is also ideal for mixing liquid and other as follows:

* Circular economy and recycling.

* Minerals and ores.

* Fertilizers, chemicals, fine chemicals.

* Food and pharmaceuticals

* Batteries

* Cosmetic Industry

* Agriculture Industry

* Ceramic Powders

* Chemicals

* Plastic Powder

* Polymer

* Chewing gum

* Sealant

* Fertilisers

* Spices and Seasonings

* Plastic Powder

* Muffin Mixture

* Household cleaners

* Food Powders

* Fondant Paste

* Activated Carbon

* Bath Bombs

* Crayon and pencil lead

* Inks

* Pigments

Operation of Paddle Blender Mixer

1.Wear you protective tools including goggles, safety boots ear protection and glove.

2. Ensure all guards and covers are in place before using the mixer machine.

3. Ensure the paddles are rotating before adding the material to be mixed. Stop the paddles before dumping the

mix.

4. Do not move the paddle mixer machine while the drum is full or while the engine is running.

5. Do not attempt to repair or service the blending mixer machine while it is running.

6. Stop the engine if leaving the paddle mixer machine unattended.

7. The exhaust and other parts get very hot in use; Be careful not to burn yourself.

8. You must dispose of the waste from unused mixes properly; follow the instructions on the

manufacturer’s container or leaflet.

9. You must clean the paddle mixer and especially the drum and paddles as soon as you have finished work before the mix goes hard

Choose Your Agitator: Double Ribbon or Paddle-Ribbon?

Double-Ribbon Agitator

The double-ribbon blender agitator is valued for its thorough mixing. It consists of an inner and an outer ribbon providing counter-directional flow while keeping the product in constant motion throughout the vessel. The inner ribbons move materials toward the ends of the ribbon blender whereas the outer ribbons move material back toward the center discharge of the ribbon blender.

Paddle-Ribbon Agitator

The paddle-ribbon agitator combines inner ribbons with outer paddles. The paddle-ribbon blender is especially well suited for fragile, heat sensitive products. While maintaining counter-directional flow, the outer paddles minimize pinch points at the wall thus introducing less frictional heat than a continuous outer ribbon.

Different Material Available

*201 Stainless Steel

Although the corrosion resistance of 201 stainless steel is not strong, but it still has good anti-corrosion properties, if the material being to mixed is not strong corrosive, then the affordable 201 stainless steel material may meet with your basic needs .

*304 Stainless Steel

304 stainless steel is a common type of stainless steel material, the household appliances you are using are probably made of 304 stainless steel. It has better corrosion resistance than 201 stainless steel and better quality ,of course ,its material cost is higher.

*More Options

Depending on your use scenario, there are many options for steel. If your product is a very corrosive chemical, the more expensive 316 stainless steel may be the best chose, accordingly, it is more expensive, but it is worth it.

Reviews

There are no reviews yet.