Description

A twin screw extruder are versatile equipment used to precess and extrude various materials, particularly polymers and plastics , into the desired shape and size. The twin screw extruder machine provide a efficient process for mixing, kneading, and homogenization of the material being processed, it is mainly used for test or lab research with small capacity and small batch production ,widely used in unversity &colleage lab, chemical enterprise, scientific research institution etc.

This twin scew extruder is suitable for processing PP, PE, PP-R, ABS and other plastics. The Mini granulator extruder machine is mainly used for test or lab research with small capacity and low energy consumption, it is great laboratory extruding equipment,widely used for chemical enterprise, scientific research institution, college and university lab etc

Through a series of procedure of heating, mixing, shearing, plasticizing and compacting the exhaust, the material is plastified into a uniform melt, and extruded into round strips. The long strips material would be cooled by water in the cooling water tank or be air-cooled, then pelletized by a pelletizer to obtain plastic pellets.

Our single and twin screw extrusion machines excel in producing sheet, pellets, PVC pipe, window profiles, vinyl siding, and profiles of wood and natural fiber plastic composites.

Simptek machine is an expert plastic extrusion manufacturer, we provide a fully customizable range of plastic polymer extruders for a variety of sizes, applications and materials.

From a lab scale extruder to industrial production capacity with Single and Twin-screw extruders machine , we provide every kind of bespoke extruders tailored to your needs.

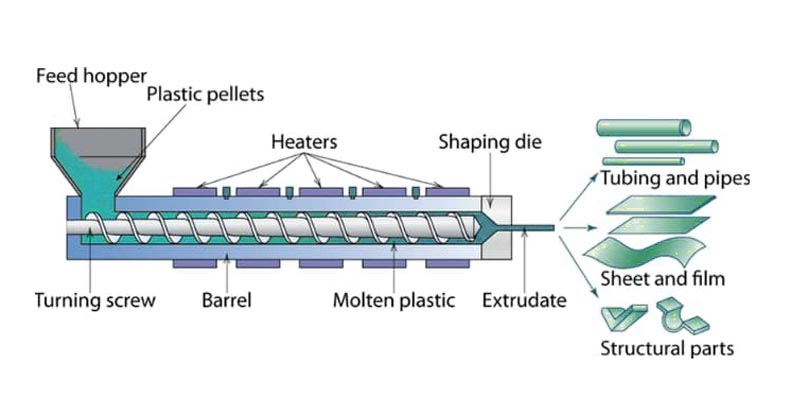

Main Components of Extruder Machine

The twin screw plastic extruding machine is one of the advanced technologies in the plastic polymer production industries, which are used to produce all kinds of plastic polymer products with different shapes and sizes. This device mainly consists of several main components as follows:

Hopper

The raw material are fed from this entry,also named as feeding funnel of extruding machine and then pushed to next process of this extrusion machine.

Screw

The spiral screw may be made of different materials such as stainless steel, aluminum or plastic. This component is mainly used to transfer the raw materials from the feeding funnel to the front and heat and melt the plastic materials.

Barrel

It is the part where screw , this barrel is usually made of stainless steel material , it has several heat channels for heating the raw materials. Basically , the barrel’s design, including its length and diameter, plays a significant role in the quality of the extrusion process.

Die

The die mold is . Just because of this die mold , the molten material passing through it and create the desired shape. The dies mold may be made of different materials such as stainless steel, polycarbonate, or plastic,it is located at the end of the extruder machine.

Electric motor

The electric motor provides the driving force of the screw. Electric motors are usually of the three-phase type and have high revolutions.

Key Feature & Benefits

* Versatility : Compatible with a wide range of material including plastic polymer, chemical,Filler Masterbatch, Color Masterbatch, Additive Masterbatch etc

* Enhanced Heat Transfer : Improved design ensured efficient heat transfer and extended component lifespan.

* Precision Control: You will never need to worry about the quality or consistency of your extruded item , as we adopt the most advanced control systems that offer accurate control over the extrusion process , ensuring your quality of goods

* Diverse Cooling Options: Offer various cooling ways including water cooled granulation ,air cooled granulation and underwater pelletizing

* Customization : Custom tailored screw configurations , feed zones ,L/D ratios , feeding and venting modes ,granulation methods and other specific requirement are provided as per specific needs ,

* Durability: Simptek’s extruder machine have been built to last, ensuring minimal downtime and reduced maintenance costs

Usage of Laboratory Extruders

Laboratory extruder machine are small scale production extruders with a variety of important uses:

*Small Batch Production

Laboratory extruder machine are ideal to provide the delivery and response time for low volume production.

*Product Development

This laboratory extrusion equipment also can be vital for a manufacturing company to develop new products and test new extrusion processes.

*Material Research and Testing

This lab extruder machine can be also used to test for new materials or different formulations before mass production.

*Quality Control

It is crucial to test the quality from several samples on a large quantity of goods ,so that ensure the constant improvement and optimization for ongoing research and development for final products.

*Education and Training

The versatile small batch table top Lab extruders can are the mostly ideal laboratory equipment for hands-on experience due to its fast changeover capability, maximize training time.

Structure Of Screw Extruder Machine

Application of Extruder Machine

Our laboratory twin screw extruder are applicable for compounding, direct extrusion, degassing (devolatilization) and reaction extrusion.

They can be used to stimulate the continuous extrusion process for batch samples, new material research, new process development and small quantity production.

The extruder machine are also applicable for the following material :

*Polymer melting, plasticizing and extruding

*Optimization of processing parameters

*Producingcast film, sheet and tube/pipe with corresponding dies.

*Optional melt pump or static mixing device can be used to improve plasticization effect

*Manual screen changer is optional to improve the purity and quality of melt.

* Filler Masterbatch

* Color Masterbatch

* Additive Masterbatch

* Biodegradable Plastic

* Cable Compounding

* Engineering Plastics

* Reinforcing (GF)

* PVC Compounding

* Polyolefin Compounding

* Reacting Direct Extrusion

* Thermoplastic Elastomers

* PET pelletizing and other

* plastic such as PE, XLPE, WPC etc

Reviews

There are no reviews yet.